Application of aluminum extrusion technology in modern industry and future development trend

Aluminum extrusion technology principle and industry application scope

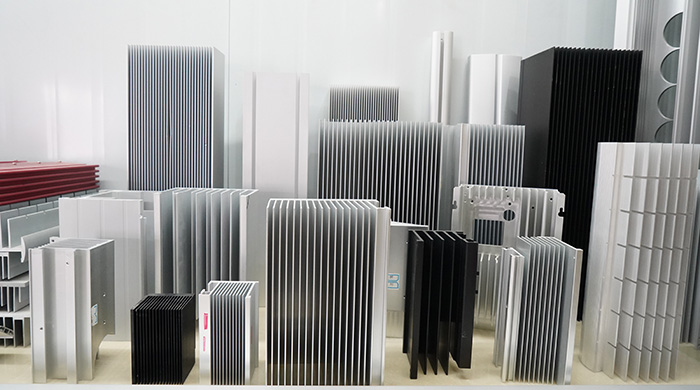

The aluminum extrusion process uses a die to apply pressure to the heated aluminum billet so that it passes through the die hole to form the required cross-sectional shape. The aluminum extrusion widely used in construction, rail transit vehicle structure, electronic housing and other fields with strict requirements on lightweight.

Lightweight trend drives demand: The development of new energy vehicles continues to drive demand for high-end aluminum.

Favorable environmental policies: Aluminum is 100% recyclable, which is in line with the sustainable development strategy.

Technological innovation and replacement: Innovative processes such as isothermal extrusion and precision molds improve product performance boundaries

Key points of sustainable development strategy for extruded aluminum profiles

In the future, the industry will focus on breaking through waste aluminum purification technology, developing extruded aluminum profiles with lower energy consumption, and establishing a full life cycle carbon footprint management system to meet environmental protection regulations. Faced with rapidly growing market demand, extruded aluminum profile companies need to continuously optimize production processes, deepen the application of intelligent manufacturing, develop green production, maintain technological innovation, and establish lasting competitive advantages in the global industrial chain.