What is aluminum extrusion profile ? What are the application and development?

According to industry data, the global aluminum extrusion market has exceeded 100 billion US dollars and is expected to continue to grow in the future. As the world's largest aluminum extrusion profile producer and consumer, China accounts for more than 60% of the world's output. In the fields of new energy, automobiles, industry, photovoltaic, transportation, etc., the aluminum extrusion industry has ushered in a new round of development opportunities.

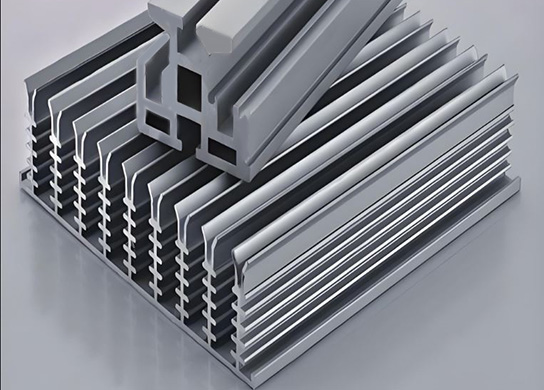

What is Aluminum Extrusion?

Aluminum extrusion process: high-temperature aluminum is passed through an extrusion machine, inserted into a mold with a certain shape and size, and extruded under hydraulic or mechanical drive to be processed into various shapes of aluminum extrusion profile such as L-shaped and T-shaped, U-shaped, H-shaped aluminum profiles, etc.

What are the application and development?

1. Lightweighting of new energy vehicles: Aluminum extrusion profiles are widely used in package frames or body structures due to their high strength and low density, thereby achieving weight reduction design of vehicles and improving safety performance, achieving lower energy consumption and longer driving range.

2. Photovoltaic and energy storage industry: In the field of new energy, aluminum extrusion profiles are corrosion-resistant and easy to install. They are important materials for photovoltaic brackets and energy storage battery shells, and are the preferred choice for solar power station construction. In 2024, the global demand for photovoltaic aluminum profiles will increase by 20%, and production expansion needs to be accelerated to meet market demand.

3. Transportation and aerospace: Aluminum extrusion profiles are widely used in rail transportation industries such as high-speed rail and subway to reduce the weight of the vehicle body. In the aerospace field, ultra-high-strength aluminum alloy extrusions are used for fuselages and internal structures, and high-end aluminum materials are further developed and applied.

Future Outlook:

Green aluminum becomes the mainstream, the world advocates the concept of sustainable development, and the proportion of recycled aluminum and low-carbon aluminum will gradually increase. By 2030, more than 30% of aluminum extrusion profiles will use recycled aluminum raw materials, deeply integrated into high-end manufacturing and green economy. Driven by policy support and market demand, the global industry is about to embrace new growth opportunities and vast business prospects.