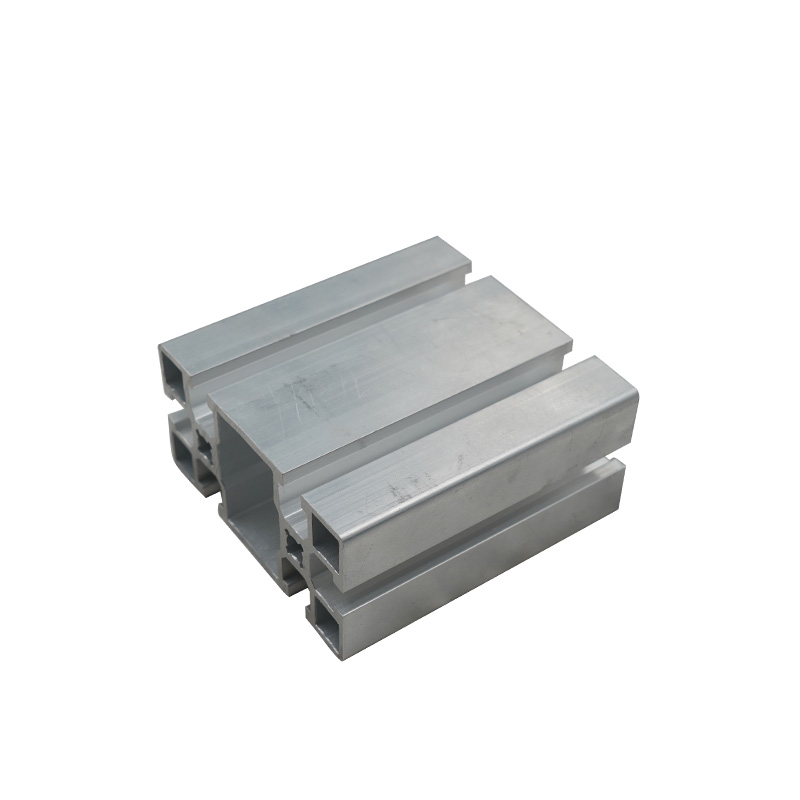

Extruded Window Or Door Extrusion Profiles

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Extruded aluminum has thermal conductivity very similar to copper, but is much lighter.

Window or door extrusion profiles has a wider range of appearance options than other materials.

Advantages of Extruded aluminum

Advantages of Extruded aluminum

Long-lasting

The corrosion resistance, corrosion resistance and weather resistance of Extruded aluminum are one of its most significant advantages. Extruded aluminum naturally rusts and resists corrosion without additional treatment. This is due to the presence of a thin, naturally occurring protective film of aluminum oxide on its surface. Through anodization, its resistance to corrosion becomes stronger.

For example, in outdoor environments, 25 micron anodizing can be performed to enhance corrosion resistance and improve surface finish. In addition, Extruded aluminum or window extrusion profiles or door extrusion profiles does not require maintenance and can be used without worrying about corrosion in most cases.

Lightweight and strong

Extruded aluminum is more than 33% lighter than steel while retaining much of its strength. Most aluminum extrusions has a tensile strength range of about 70-700 MPa, while its density is two-thirds less than steel.

Product design engineers do not have to worry about the strength of extrusion aluminum parts. It can be used as a structural part in the construction industry and the automotive industry and window extrusion profiles, and is the best substitute for other metal materials. In order to reduce weight and energy consumption, the automotive industry or window extrusion profiles or door extrusion profiles is using Extruded aluminum on a large scale.

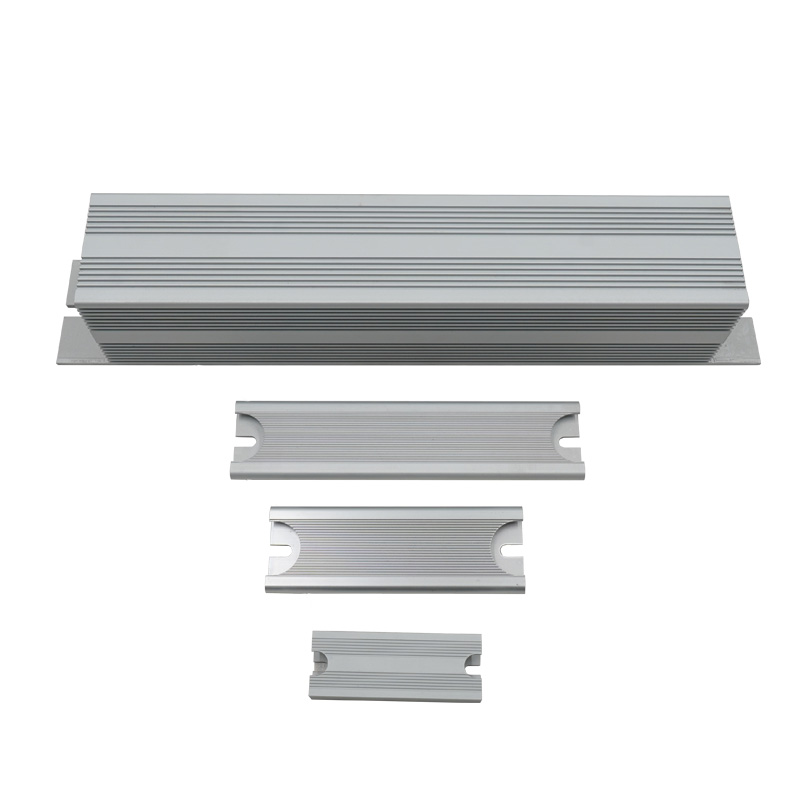

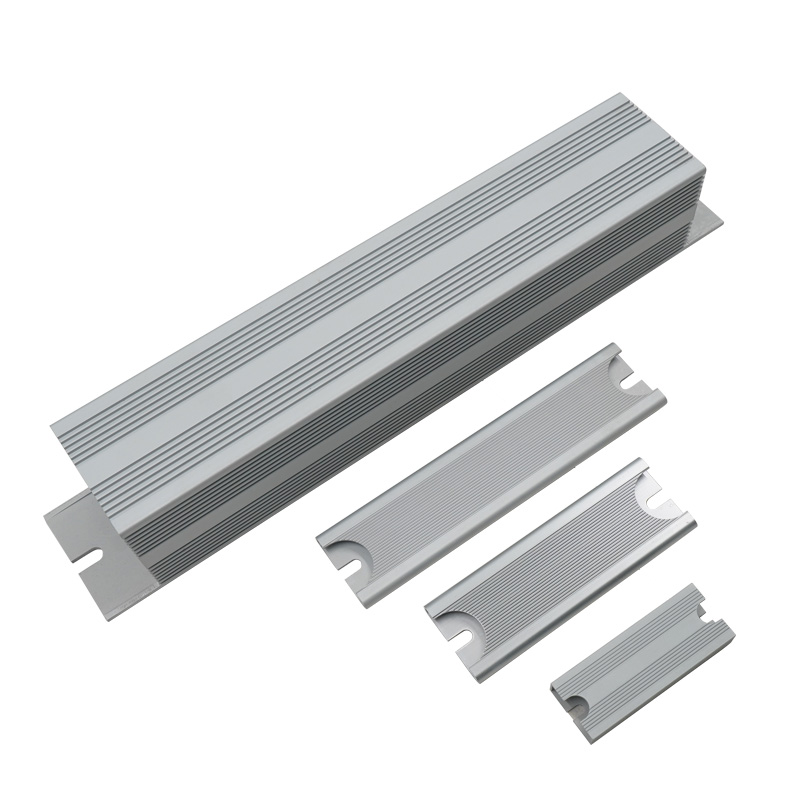

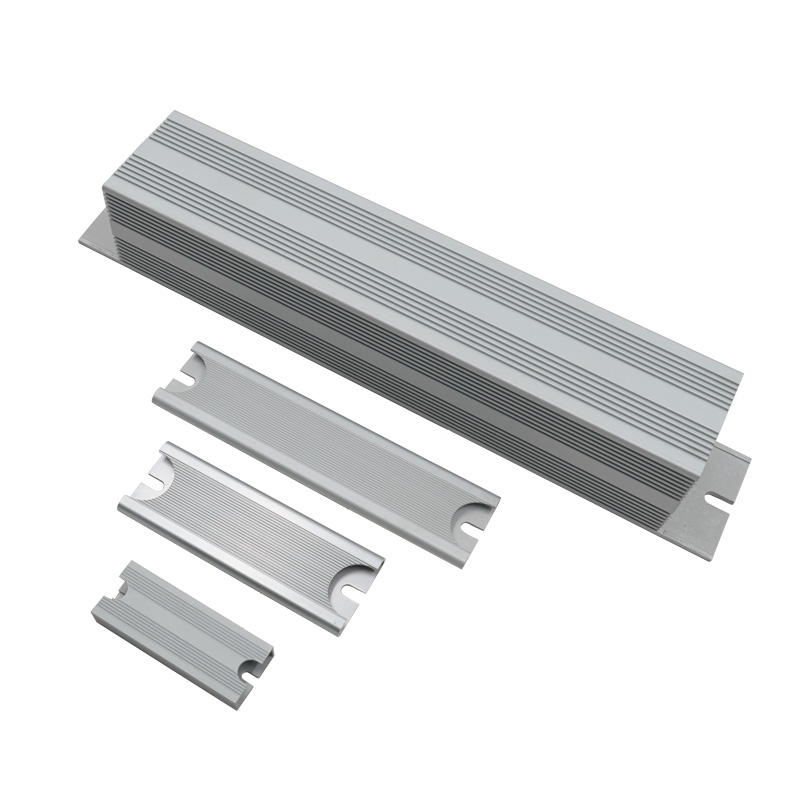

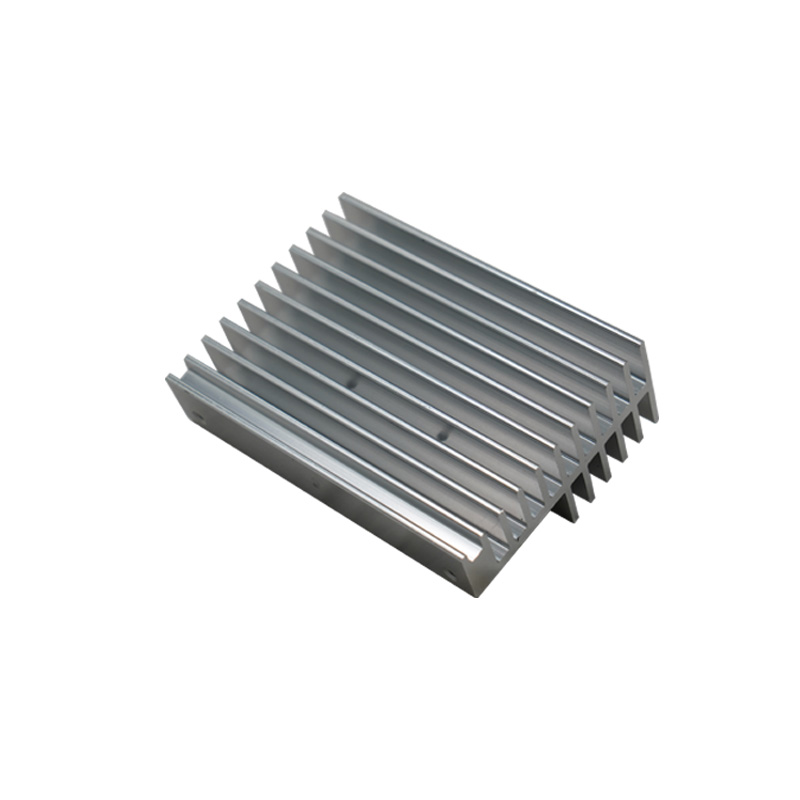

Good thermal conductivity

Extruded aluminum is an excellent thermal conductor. The contour design of aluminum extrusion can maximize the thermal conductive surface area and form a thermal channel. A typical example is a computer CPU heat sink, where Extruded aluminum is used to remove heat from the CPU.

Window extrusion profiles or Door extrusion profiles

Aluminum profiles for doors and windows are widely used in the construction industry, mainly for doors and windows, curtain walls, indoor and outdoor decoration, etc.

The specifications of aluminum profiles for doors and windows are usually marked by the height of the profile section. Common size series include: window profiles: 40, 45, 50, 55, 60, 65, 70 series (unit: mm). Door profiles: 70, 80, 90, 100, 120 series, suitable for sliding doors, swing doors, etc.

Wall thickness requirements: The wall thickness of aluminum alloy windows shall not be less than 1.4mm, and it is recommended to be greater than 1.6mm for high-rise buildings. The wall thickness of aluminum alloy doors shall be greater than 2mm, and heavy sliding doors are recommended to be above 1.6mm.