Tube Type Black Anodized Auto Radiator

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Auto radiators anodized cooling efficiency surface radiation capability increased to 0.80.

Black anodized radiators acid, alkali and corrosion resistant, anodized in various colors can be customized.

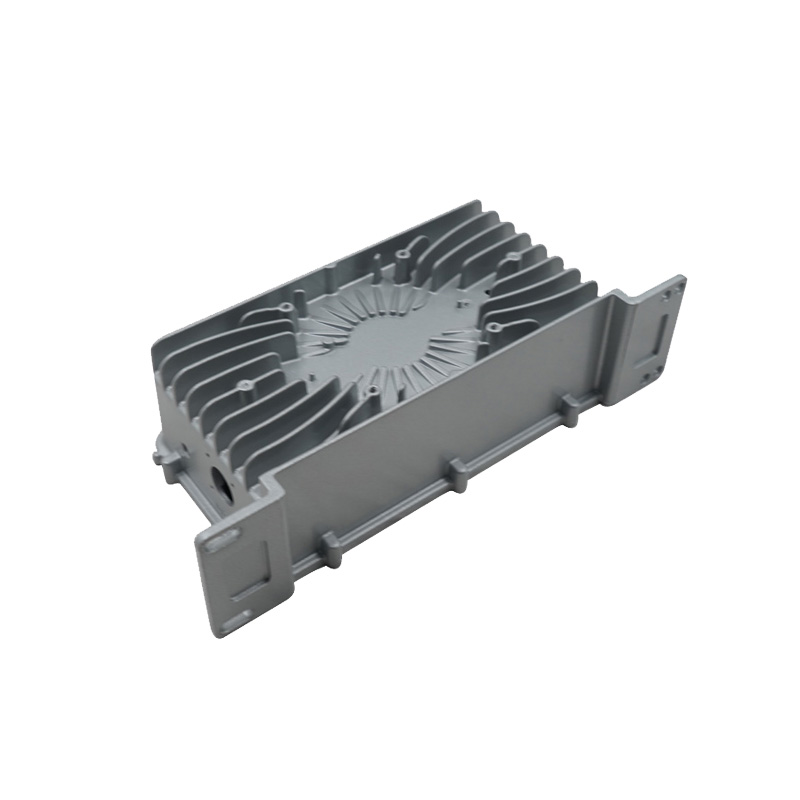

Auto tube type radiator

The tube type radiator is composed of cooling tubes and radiators. The tube type radiator cross-sections of the cooling tubes are mostly oblate. The purpose is to reduce the resistance of the air, provide sufficient heat transfer area, and complete the heat transfer between the tube type radiator , coolant and air. exchange. The tube type radiator (pipe-band radiator)is welded and arranged in alternating phases. The two parts are corrugated heat-sinks and cooling pipes. The heat dissipation capacity of the tube-strip radiator is stronger, and the heat dissipation area is about 12% larger.

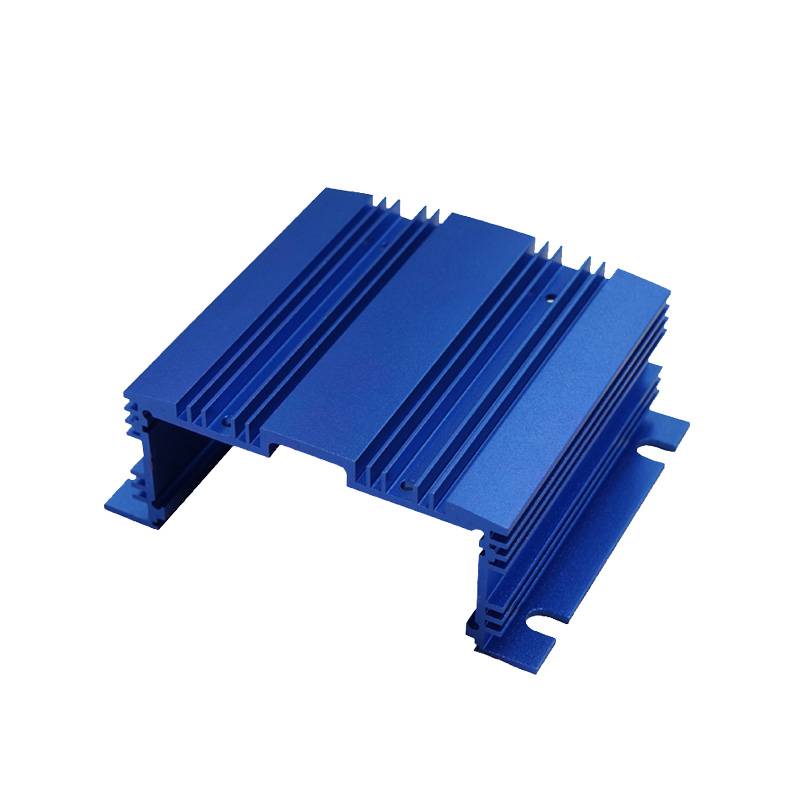

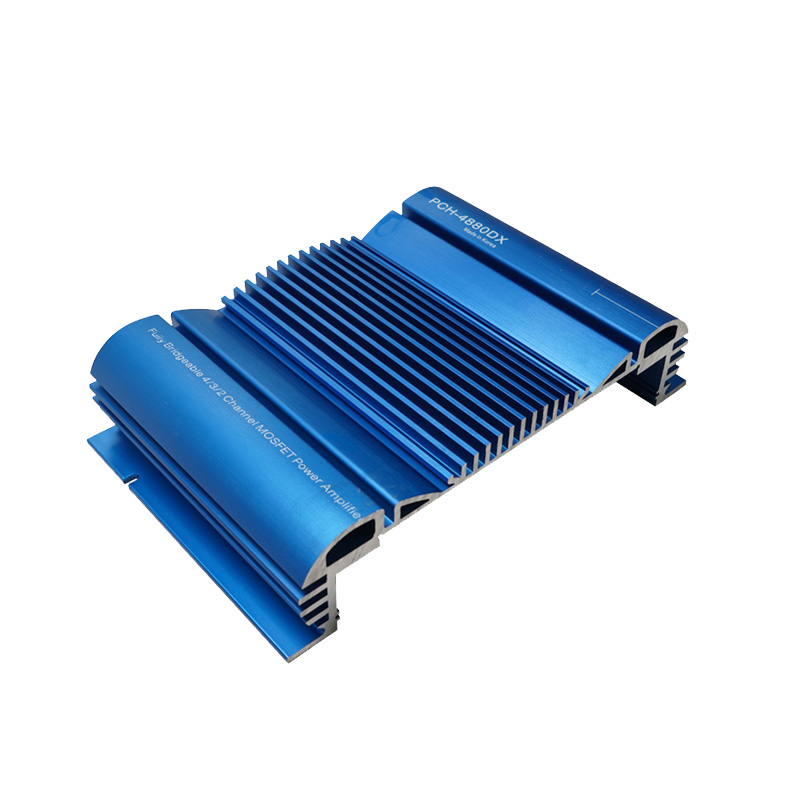

Black anodized radiators

Anodizing enhances the corrosion resistance of the aluminum surface, extending the service life of your auto radiators. The black oxide film of the black anodized radiators is not only functional, but also improves the aesthetic appearance of the radiator product. Black anodizing provides a uniform, low-profile matte surface with color stability that is less prone to fading or discoloration (better than painting or electroplating). Of course, auto radiators anodizing can be customized in a variety of colors for you to choose.

Effect of surface treatment on three properties

1.Wear resistance - the surface of ordinary aluminum alloy has a typical "natural aluminum" color, the microlayer is easily oxidized, the hardness of aluminum is soft, and the wear resistance is low. After black anodization, the surface is treated with spot oxidation, and hard AI2Q3 is deposited in the formed oxide layer to make the auto radiators more wear-resistant.

2. Chemical resistance - Aluminum easily reacts with acids and bases, and even fingerprints can easily oxidize the aluminum itself. The anodized black anodized radiators is not prone to chemical reactions with acids and alkalis under harsh conditions, greatly ensuring durability.

3. Cooling efficiency - the most important parameter is the extremely low untreated surface radiation capability. The radiation rate of natural aluminum is only 0.05, which is too low. After anodizing the radiator, the emissivity can be increased to 0.80, which helps heat transfer and promotes heat dissipation of auto radiators.

The auto radiators is a key component to ensure the stable operation of the engine. Its performance directly affects fuel economy and engine life. Regular maintenance and reasonable upgrades can effectively avoid overheating failures. For electric vehicles, the radiator also bears the task of cooling the battery and motor, which requires higher technical requirements.