Aluminum Extruder Manufacturer Explains The Importance Of Die Testing

In the high-stakes world of aluminum extrusion, where millimeter precision meets immense industrial force, rigorous testing is the unsung hero separating excellence from costly failure. For any aluminum extruder, implementing a comprehensive testing protocol is not merely a procedural step; it is the essential foundation for process stability, product integrity, and long-term profitability. From the raw billet to the finished profile, each test acts as a vital checkpoint, safeguarding against defects, optimizing performance, and ensuring that every length of extruded aluminum meets the exacting standards demanded by industries from aerospace to construction.

A Multi-Stage Testing Framework for the Aluminum Extruder

A proactive aluminum extruder integrates testing throughout the entire production lifecycle. This end-to-end approach can be visualized as a continuous quality loop.

· Testing begins with the raw material. Chemical composition analyses of the liquid alloy and finished billets ensure they meet strict material standards. Advanced aluminum extruder may also use ultrasound to inspect billets for internal inclusions or cracks.

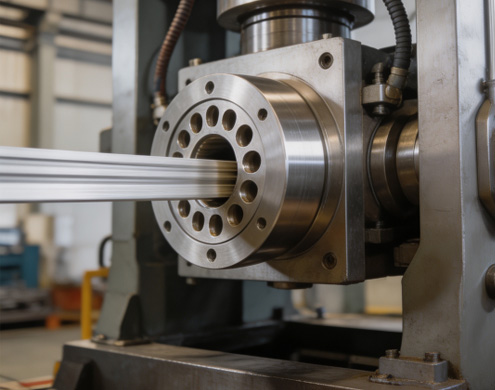

· Before full production, die testing is crucial. Best practices recommend using a short or pure aluminum billet for the initial run to minimize risk. Critical pre-checks for the aluminum extruder include verifying the precise alignment of the press center and ensuring dies are preheated to the correct temperature for a sufficient duration to prevent thermal shock and ensure even material flow.

· Leading-edge aluminum extruder are adopting hybrid monitoring systems that combine infrared and visible-light cameras to inspect the profile surface as it exits the die. The thermal image reveals temperature distribution anomalies indicating process instability, while the visual image detects surface defects like scratches or tears. This allows for immediate correction, moving quality control from a reactive to a proactive stance.

· After extrusion and aging, aluminum extruder profiles undergo rigorous verification. Dimensional inspection using 2D or 3D coordinate measuring machines ensures compliance with geometric tolerances. Mechanical properties, such as tensile strength, are confirmed through standardized tensile tests.

·This stage includes visual inspection, roughness tests, and checks for straightness and torsion. For critical applications, further tests like leak checks or examination of welded joints may be performed.

In today's precision-driven manufacturing landscape, an aluminum extruder cannot afford to view testing as an isolated cost center. It is a strategic imperative and a core component of operational intelligence. By embracing a holistic testing philosophy—leveraging both established practices and innovative on-line monitoring technologies—the forward-thinking aluminum extruder ensures not just the quality of its products, but the very resilience and sustainability of its business.