Aluminum radiators continue to evolve in various industries

Aluminum radiators continue to evolve in various industries

Driven by innovations in automotive and industrial cooling, the humble aluminum radiator is undergoing a high-tech transformation. From electric vehicles to wind power generation, these efficient heat exchange components have become indispensable. Recent advances in materials science and manufacturing processes are pushing the boundaries of what's possible with aluminum radiators, making them lighter, thinner, and more efficient than ever before.

High-efficiency aluminum radiator market expansion

The global high-efficiency aluminum radiator market is experiencing significant growth, driven by rising demand from mechanical engineering, the automotive industry, and wind power generation. According to a recent report, the market is expected to maintain steady growth from 2020 to 2031, with China remaining a leading producer and consumer.

A variety of aluminum radiator types

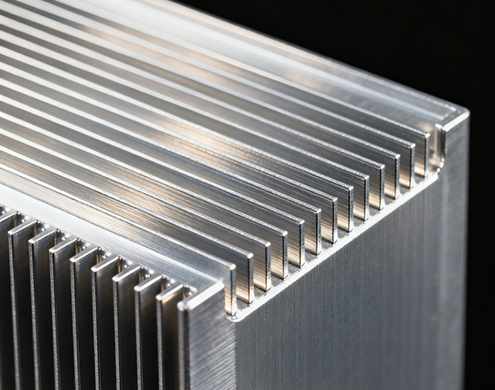

Aluminum radiator are primarily categorized into three types: die-cast aluminum, extruded aluminum, and composite aluminum. Each type meets the needs and performance requirements of different industries. Die-cast aluminum radiator are valued for their integral casting, making them an ideal choice for critical applications. Extruded aluminum radiator, also known as radiator aluminum profiles or sunflower aluminum profiles, offer outstanding aesthetics, lightweight properties, excellent heat dissipation, and energy savings.

Aluminum radiator Manufacturing Process

For extruded aluminum radiator, the process begins with melting aluminum ingots (AL99.70 or higher), aluminum-silicon alloy ingots, and magnesium ingots at temperatures between 730°C and 750°C. After stirring, and refining, the radiator is cast. Surface treatment plays a crucial role in enhancing durability, with anodizing, electrolytic coloring, sealant application, and electrophoresis coating enhancing corrosion resistance, wear resistance, and aesthetics.

Applications span numerous industries

Aluminum radiator have become crucial in the automotive sector, particularly with the rise of electric vehicles. Ultra-thin all-aluminum heat sinks have been developed, reducing thickness by up to 43%, while improving energy efficiency by 8% and reducing weight by up to 8%. The electronics industry relies heavily on aluminum heat sinks for cooling computers, appliances, and electronic devices, as effective heat dissipation is crucial for performance and longevity.

As industries around the world continue to focus on energy efficiency, space optimization and environmental responsibility, aluminum heat sink technology continues to demonstrate outstanding innovation and improvement capabilities and will play an increasingly important role in thermal management systems.