What You Need to Know About Copper and Aluminum Heatsinks

What You Need to Know About Copper and Aluminum Heatsinks

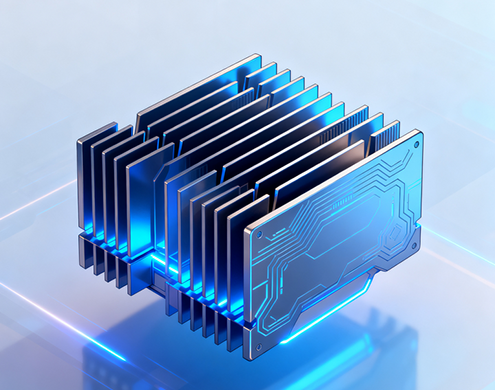

Copper Heat Sinks vs. Aluminum Heat Sinks: A Materials Battle Shaping the Future of Cooling Technology. In the race to cool everything from smartphones to electric vehicles, the choice between copper and aluminum is becoming a critical decision, with profound implications for performance, sustainability, and cost.

The evolution of cooling technology mirrors the broader trajectory of modern electronics—electronic devices generate significant amounts of heat. Copper and aluminum. While copper has long been favored for its superior thermal conductivity, aluminum, with its advantages in weight, cost, and manufacturing, is now challenging it across multiple industries.

Weight density of aluminum and copper heat sinks:

The weight difference is particularly significant—copper has a density of 8.96 g/cm³, approximately 3.3 times that of aluminum, compared to aluminum's density of 2.7 g/cm³. This weight difference has profound implications for industries like automotive and aerospace, where every kilogram saved directly impacts fuel efficiency and performance.

The automotive industry: The rise of aluminum

The electric vehicle industry has become a key battleground for thermal management solutions. Aluminum has garnered significant attention due to its significant weight advantage. According to industry analysis, replacing copper with aluminum in electric vehicle battery thermal systems can reduce weight by up to 70%—a crucial consideration, as every 10 kg saved translates to a 1-2% increase in driving range.

Technological Innovation: Closing the Performance Gap

Recent manufacturing advancements have narrowed the performance gap between aluminum and copper solutions. Aluminum extruded Heat sinks fin technology now enables the production of ultra-thin fins as narrow as 0.3 mm, while the practical limit for copper fins is approximately 0.5 mm. This allows aluminum heat sinks to compensate for their lower thermal conductivity by increasing surface area.

The evolution of heat dissipation technology mirrors the broader trajectory of modern electronics—a relentless pursuit of greater efficiency within the face of ever-changing constraints. At the heart of this struggle lies the choice of two metals with strikingly different properties: copper Heat sinks and aluminum Heat sinks . Aluminum is popular for a reason, but copper also has its uses. Cost and weight savings are key factors in aluminum's popularity in heat sinks. Die casting and CNC machining allow for more complex geometries, and extruded aluminum heat sinks can meet the needs of most projects. If you would like to learn more, please contact us.