Global aluminum extrusion market growth and development

The global aluminum extrusion market is expected to expand significantly in the future, reaching approximately $101.82 billion in 2025, with a compound annual growth rate (CAGR) of 8%. This growth is primarily driven by growing demand from the automotive and construction industries, where the lightweight, high-strength, and recyclable properties of aluminum extrusions are becoming increasingly important.

Aluminum Extrusion Growth Drivers and Industry Trends:

Automotive lightweighting is a driving force behind aluminum extrusion, particularly in the electric vehicle (EV) sector, driving the primary application of aluminum extrusions.

· Electric Vehicles (EV): Aluminum extrusions are crucial for battery housings, structural components, and underbody structures in EV. Their use helps offset the weight of the battery, directly extending vehicle range.

· Material Substitution: Both traditional automakers and EV manufacturers are increasingly using aluminum to replace heavier materials such as steel. This shift is driven by the need to meet stringent global emissions standards and improve fuel economy.

Aluminum Extrusion in Construction and Infrastructure Expansion:

The construction industry remains the largest consumer of aluminum extrusions, accounting for over half of global usage. Rapid urbanization is driving demand for residential and commercial buildings. Global investment in sustainable construction and green building initiatives, driven by aluminum's durability and recyclability, is also driving demand.

Future Opportunities for Aluminum Extrusion

· Sustainability and Recycling: Aluminum's inherent recyclability is a major advantage. The process of recycling aluminum saves approximately 95% of the energy required to produce primary aluminum from ore. This aligns perfectly with global sustainability trends and circular economy goals, which encourage the use of recycled materials in products.

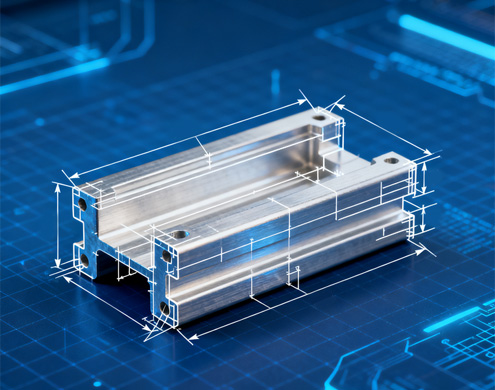

· Expanding into New Applications: In addition to traditional markets, aluminum extrusions are finding new applications in the renewable energy sector, such as solar panel mounting structures, and the electrical and electronics industries.

· Product Development for Niche Markets: The growth of consumer-oriented markets, such as 3D printing and the do-it-yourself (DIY) sector for customized furniture, is creating new and dynamic sales channels, as evidenced by strong online retail sales figures for standard extrusions.

The future of the aluminum extrusion industry is bright, with automotive lightweighting and global construction activity as key demand drivers. Future success depends on the industry's ability to address challenges such as energy costs and competition through continued technological innovation, a strong focus on sustainability through recycling, and the ability to seize opportunities in emerging industries and applications.