What is anodized of aluminum Heatsinks?

What is anodized of aluminum Heatsinks?

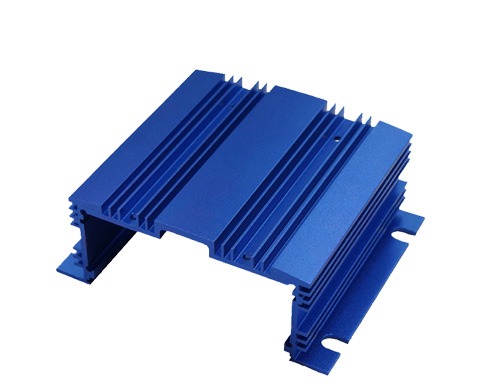

Breakthroughs in anodized aluminum heatsinks technology significantly improve heat dissipation efficiency. The thermal management industry is experiencing a significant shift toward anodized aluminum heat sinks due to their superior heat dissipation performance and durability. Recent advances in anodizing technology have optimized the microstructure of the oxide layer, increasing the efficiency of heat conduction and radiation. This makes them ideal for high-power applications such as LED lighting, audio amplifiers, and industrial electronics.

What is the Anodizing Process?

Anodizing is an electrochemical process in which parts are placed in a bath of electrolyte and subjected to a direct current. This process thickens the naturally occurring oxide layer on the metal surface, creating a porous surface that protects the metal from corrosion.

Anodized aluminum heatsinks align with the trend toward green manufacturing. This process avoids the use of toxic plating chemicals, resulting in an environmentally inert oxide layer. Quality control is ensured by non-destructive testing tools, such as XRF technology, which measures coating thickness (5-25 microns) and composition without damaging the product.

What are the advantages of anodized heat sinks?

Anodizing aluminum heat sinks offers key advantages, including: enhanced corrosion resistance; improved wear resistance; enhanced insulation; and increased surface emissivity.

Anodized aluminum heat sinks offer significantly higher thermal conductivity than traditional cast aluminum designs. Their thickened pure aluminum structure and oxidized surface keep the temperature only 38°C above ambient at a 100-watt load, ensuring stability over extended use.

Another benefit of anodizing aluminum is the ability to add color dyes and its fade-resistant properties. Anodized heat sinks can be dyed in various colors, including black, blue, red, and green. The color itself has only a visual effect on the heat sink; regardless of the color, the heat dissipation effect remains unchanged.

Anodized Heat Sink Market Outlook

Global demand for anodized aluminum heat sinks is expected to grow at a rate of 15% annually, driven by emerging applications such as new energy vehicles, 3D-printed custom parts, and high-performance computing. Manufacturers are increasing their investment in CNC machining and surface finishing technologies to provide precise thermal solutions.

Anodized aluminum heat sinks combine efficiency, durability, and environmental friendliness. As electronic devices continue to push power limits, these components will remain critical to maintaining cooling, reliability, and sustainability, fueling innovation.