Which aluminum material is best for extruded heatsinks?

Which aluminum material is best for extruded heatsinks?

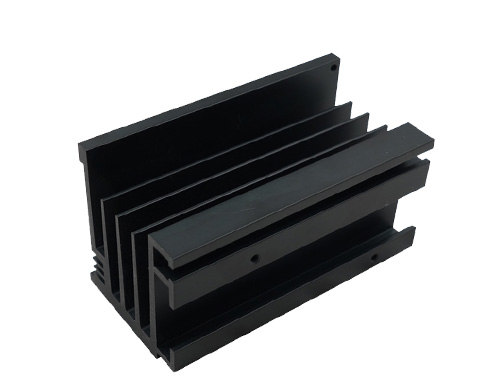

When it comes to thermal management, aluminum extruded heatsinks remain one of the most cost-effective solutions for cooling electronic components. For LED lighting and consumer electronics, the choice of aluminum significantly impacts cooling system performance, surface finish, and cost. Based on in-depth industry analysis, we present a guide to the best aluminum materials for extruded heat sinks.

Why choose aluminum over copper?

Aluminum is the most common material choice. Furthermore, copper offers better thermal conductivity. In fact, copper's thermal conductivity is approximately 60% higher than aluminum's. However, aluminum extruded heatsinks is suitable for most applications and can be produced relatively cost-effectively through mass injection molding.

Top-Quality Aluminum Alloys for Extruded HeatSinks

6063 Aluminum Alloy: The Industry Standard

6063 aluminum alloy is the most commonly used material for extruded heat sinks, comprising approximately 75% of all extruded heatsinks. This material offers an optimal balance of thermal performance, extrudability, and mechanical strength.

Key Advantages of 6063 Aluminum Alloy:

· Excellent formability, enabling the fabrication of complex geometries.

· Excellent surface finish and good heat dissipation.

· Excellent balance between weight and strength.

· Facilities equipped for anodizing and other surface treatments.

· Typical applications: Consumer electronics, LED lighting, power amplifiers, telecommunications equipment, and industrial automation systems.

6061 Aluminum Alloy: The Strength Choice

6061 aluminum alloy offers higher mechanical strength than 6063 aluminum alloy, but has a slightly lower thermal conductivity of approximately 155-167 W/m·K. It is suitable for applications requiring structural integrity and good heat dissipation.

Key Advantages of 6061 Aluminum Alloy:

· Higher mechanical strength than 6063 grades

· Good machinability for subsequent processing

· Good thermal properties

· Good corrosion resistance

Typical applications: Aerospace, industrial power systems, and applications requiring additional structural support.

Making the Right Choice for Your Project

The thermal conductivity differences between the 6000 series alloys are relatively small. Whichever alloy you choose, making sure the extruded heat sink fits the heating element as closely as possible will help ensure the success of your project.