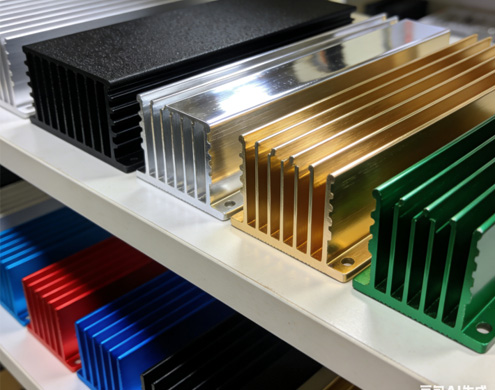

Surface Treatment And Painting Knowledge Of Aluminum Extruded Heat Sinks

Breakthroughs in Surface Treatment Technology Enhance the Performance of aluminum extruded heat sinks. Emerging technologies are bringing new efficiency improvements to critical cooling components. For engineers and purchasing experts, choosing the right aluminum extruded heat sinks is not just about its geometry. The surface treatment employed significantly impacts its heat dissipation performance, corrosion resistance, and lifespan. Recent advances and research reveal that innovations in surface treatment technologies—from chemical roughening to advanced composite coatings—are pushing the limits of what these critical heat dissipation components can achieve.

Improving Heat Transfer Efficiency of Aluminum Extruded Heat Sinks Through Surface Engineering.

The primary goal of surface treatment is to improve the heat dissipation efficiency of aluminum extruded heat sinks. Research shows that simply altering the surface texture can yield significant improvements.

• Chemical Polishing: Using hydrochloric acid to create micro/nano-level roughness on the surface of conventional extruded aluminum heat sinks increases the convective heat transfer coefficient by more than 50% compared to smooth surfaces, providing a scalable alternative to expensive additive manufacturing technologies.

• Radiation Surface Coating: Thermal radiation is another key heat transfer pathway. Coating aluminum alloy heat sinks with a composite material of copper oxide (CuO) and silicone-based resin significantly improves surface emissivity. This results in a significant reduction in LED junction temperature and overall thermal resistance of the heat sink assembly.

• In addition to thermal performance, protecting aluminum extruded heat sinks from environmental corrosion is crucial, especially in harsh or long-life applications. The industry is moving away from traditional anodizing and chromate conversion coating technologies.

• Advanced Protective Coating: This process involves laser melting, followed by the deposition of a diamond-like carbon layer and a graphite-like carbon layer using ion plating technology. This gives the heat sinks internal surface excellent corrosion resistance while maintaining good thermal conductivity.

• Nanocoating Innovation: A patented electrostatic spraying process using nanopowder coatings is designed to significantly improve the mechanical hardness, heat resistance, and corrosion resistance of the heat sinks internal surface.

The surface of an aluminum extruded heat sinks is far more than just an aesthetic product; it is a crucial engineering interface that plays a decisive role in heat transfer, environmental adaptability, and assembly integration. From simple chemical etching to complex vapor-deposited diamond-like carbon layers, advancements in surface treatment technologies have provided engineers with powerful tools that will become increasingly critical in effective thermal design.