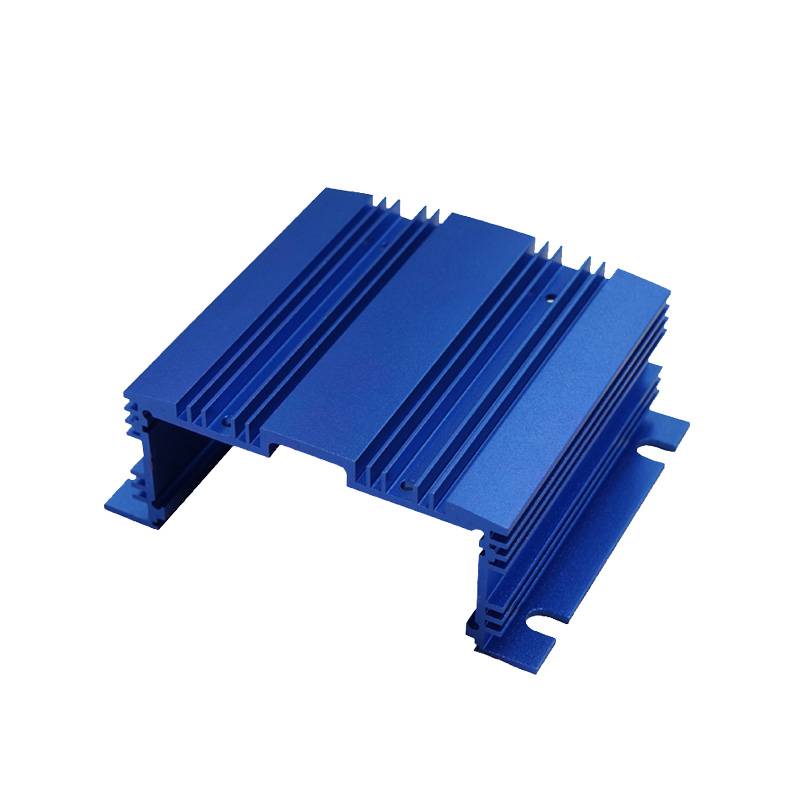

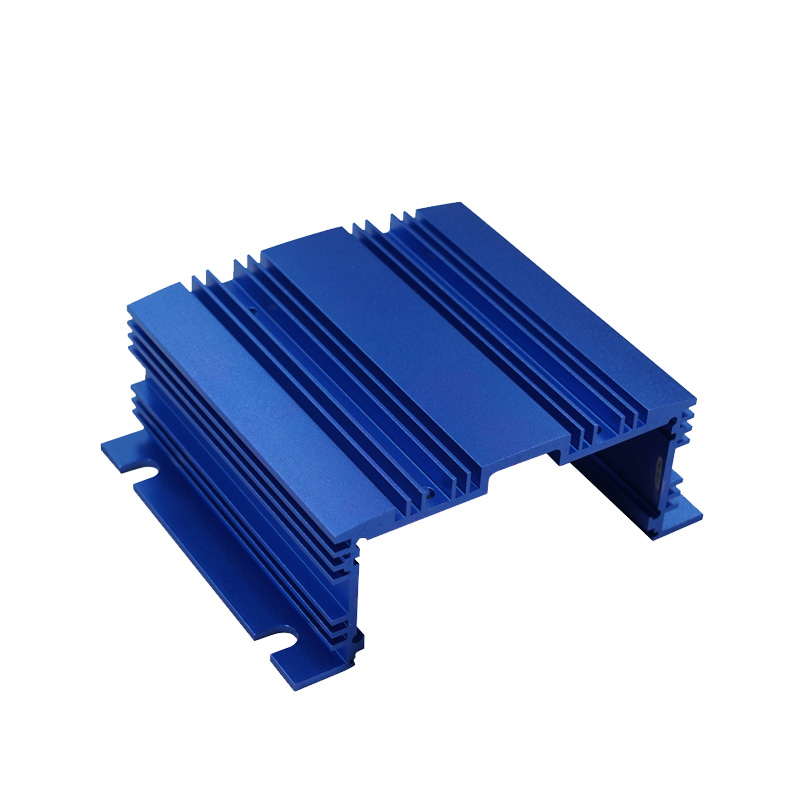

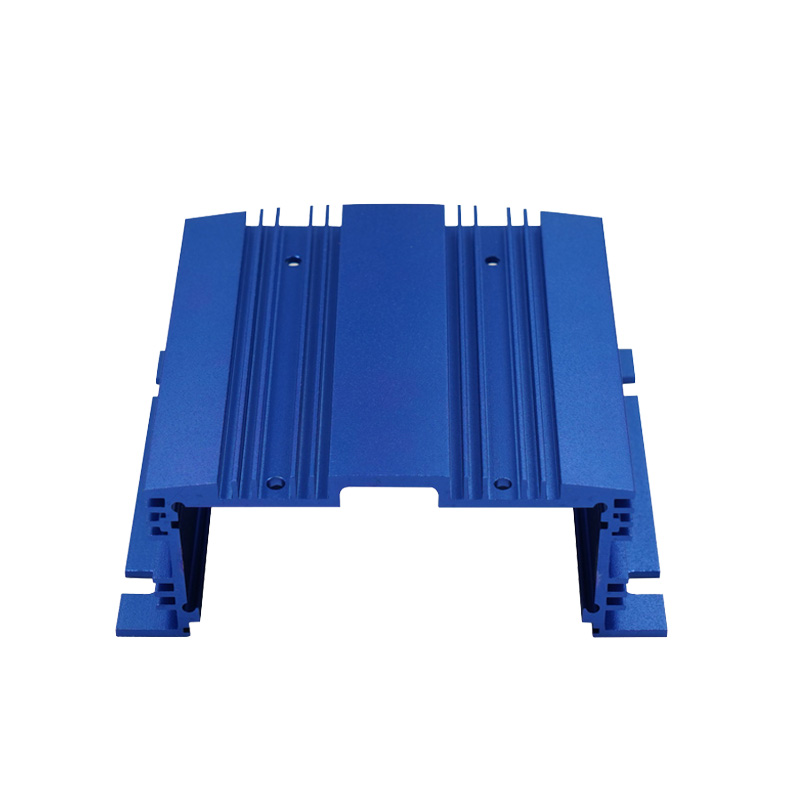

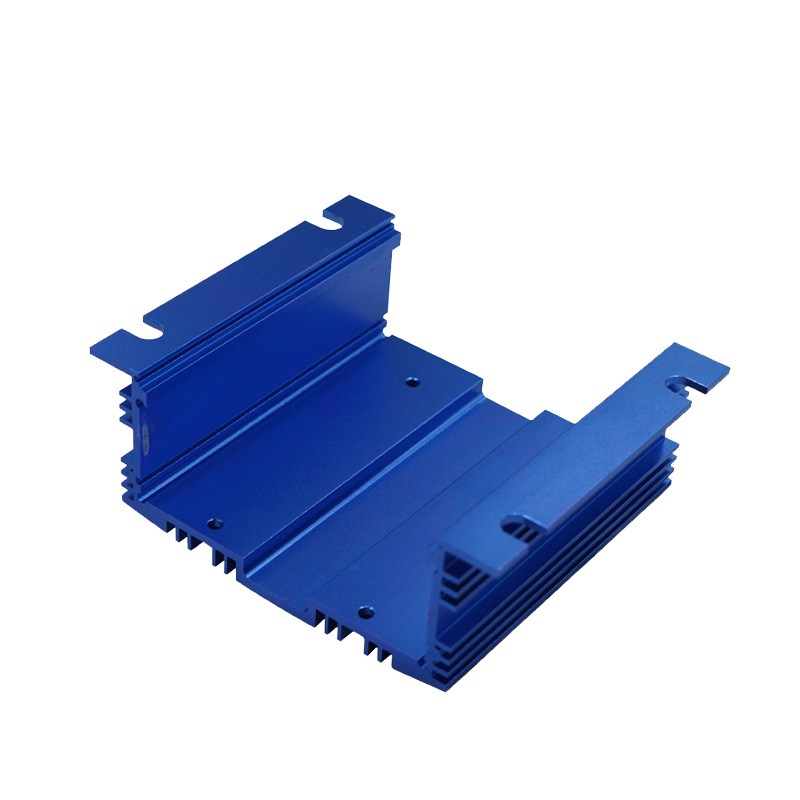

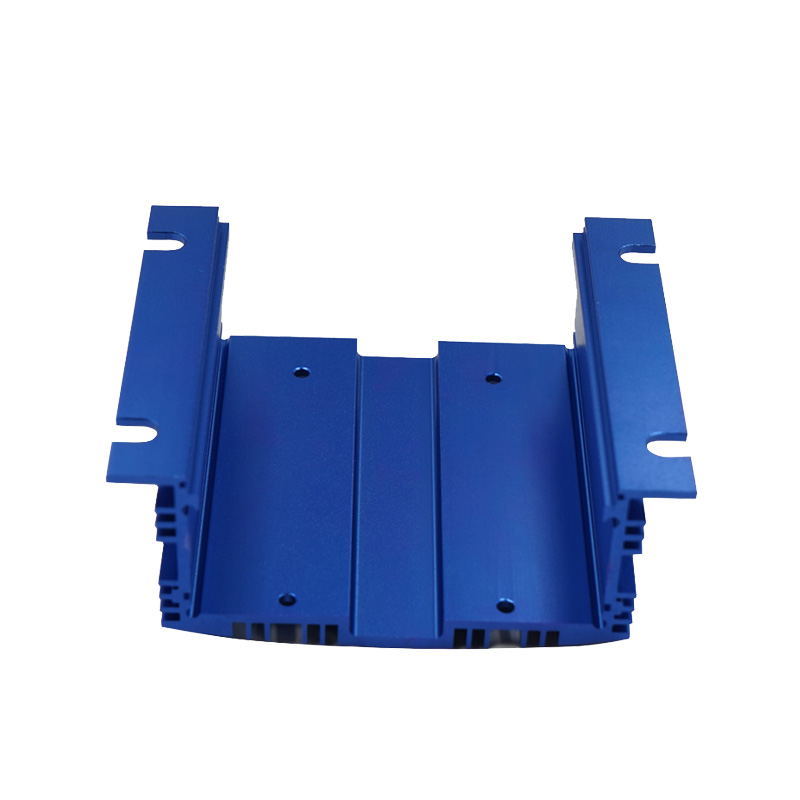

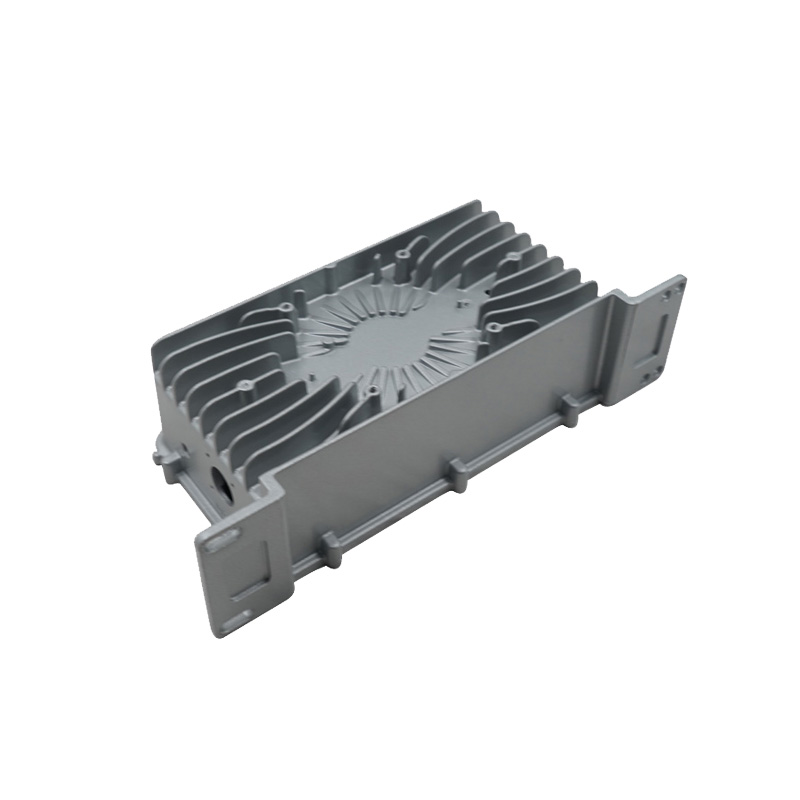

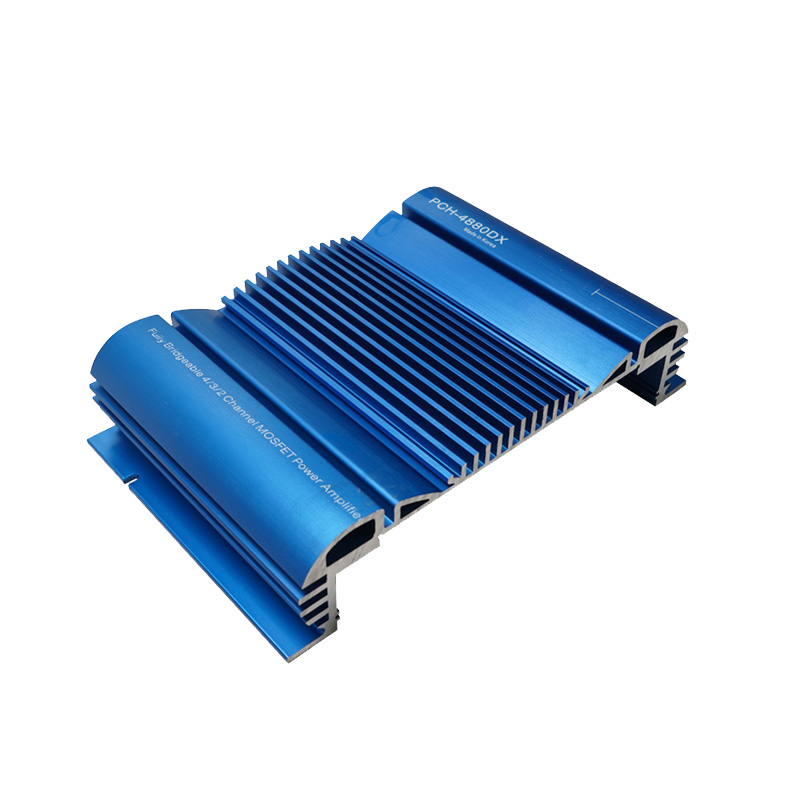

CNC Machined Heatsink Automobile Radiator

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Custom designed CNC Machined radiators that perfectly meet cooling requirements.

Heat sinks Automobile can be precision engineered with specific fin configurations, airflow patterns and materials.

CNC Machined Heatsink Automobile Radiator

| Application Industry | Metal | Description |

| Chassis components | Aluminum, Steel | Extruded parts that form the vehicle frame, adding structural strength. |

| Engine parts | Aluminum, copper | Components such as heat exchangers improve engine efficiency and cooling. |

| Transmission shaft | Steel, Aluminum | These are essential for transferring power from the engine to the wheels, ensuring the vehicle runs smoothly. |

| Door frame | Aluminum, Steel | Provides structural support and contributes to vehicle safety in the event of a side impact. |

| Suspension | Aluminum Plate | Coponents that absorb shocks, improving ride comfort and handling. |

| Crash Management System | Aluminum Plate | Extrusions are designed to absorb and disperse the impact energy in a crash, protecting the occupants. |

Advantages of CNC Machined radiator of automobile

High precision

As a key component in the automotive engine cooling system, the heatsink Automobile requires high precision to ensure stability and efficiency. CNC machining can accurately control the movement trajectory of the tool and the processing size of the workpiece, ensuring the manufacturing accuracy of the heatsink Automobile and improving product quality.

High efficiency

CNC Machined radiator can realize automated processing, improve processing efficiency, reduce the possibility of manual errors, and can perform a variety of processing operations, such as milling, drilling, tapping, etc., greatly improving production efficiency.

Flexibility and adaptability

By pre-writing CNC programs, CNC machine tools can flexibly adapt to the processing needs of different CNC Machined radiator, realize personalized customized production, and can adjust specifications and sizes or change structural forms to meet the diverse needs of the market.

Good repeatability

During the production process, CNC machining can ensure the consistency of the processing quality of each heatsink Automobile component, avoid differentiation caused by manual operations, and ensure product consistency and reliability.