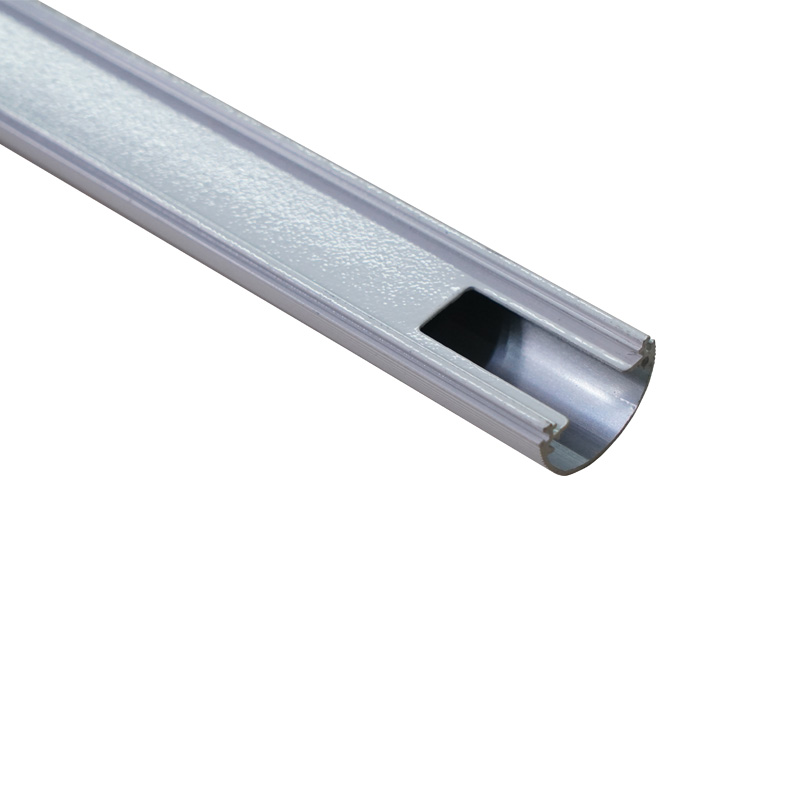

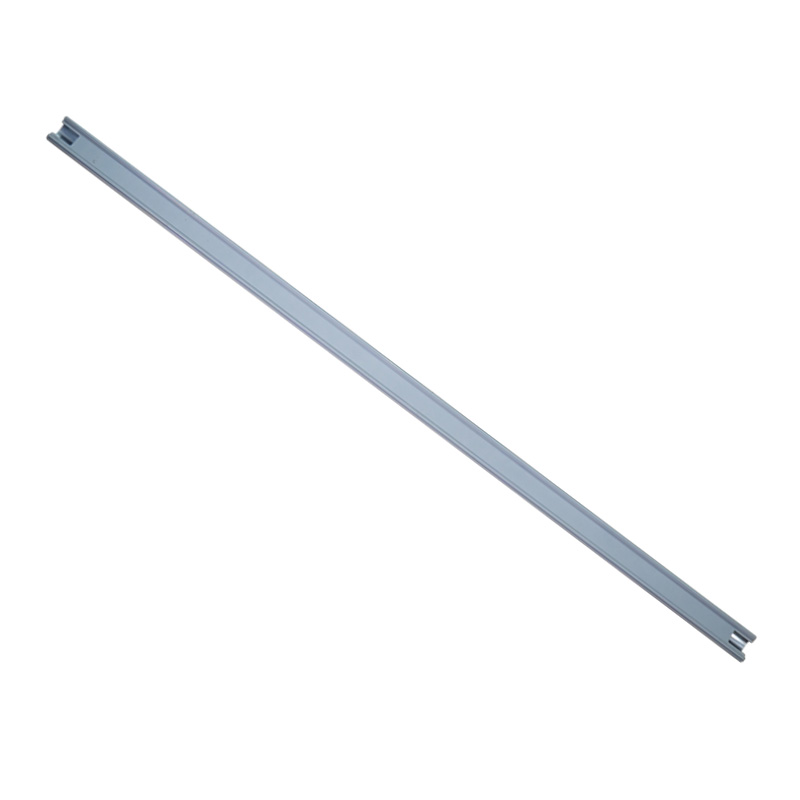

Aluminum Alloy LED Photovoltaic Radiator Profile

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Aluminum alloy profiles have relatively low energy consumption, which reduces mold and manufacturing costs.

Led aluminum radiator plays a vital role in maintaining LED temperature and preventing overheating conditions.

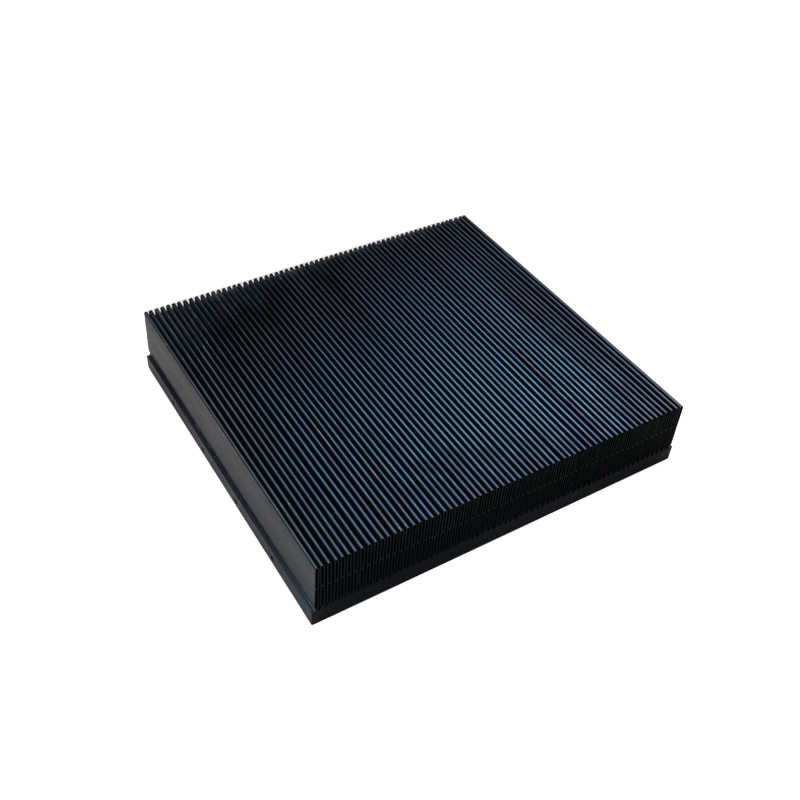

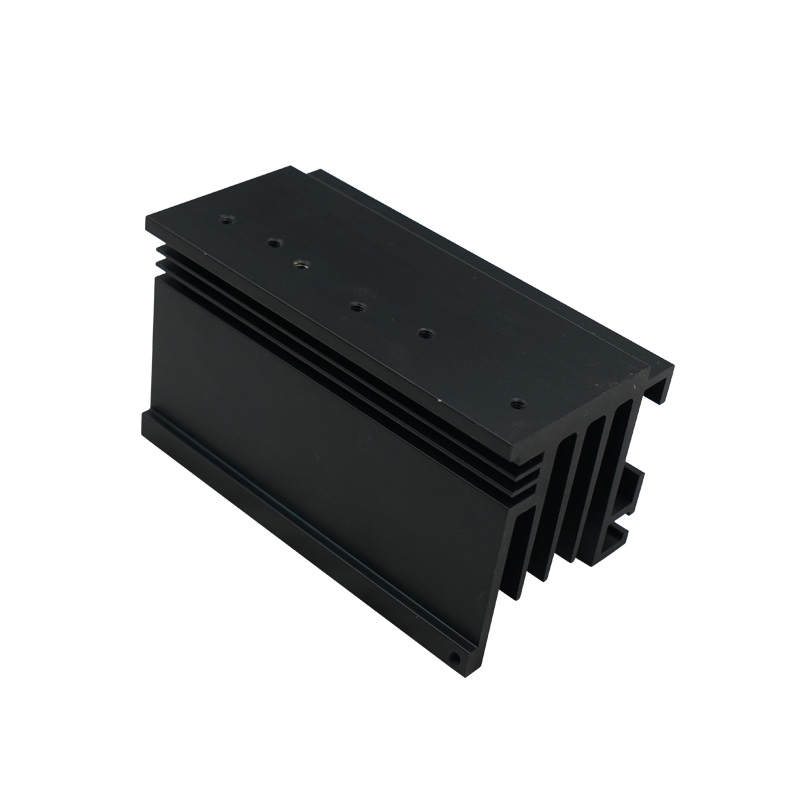

The role of LED Photovoltaic aluminum radiator

Electronic components in photovoltaic aluminum radiators, such as transistors, transformers, capacitors, etc., will generate heat energy during operation. Photovoltaic Led aluminum radiators protect electronic components from overheating damage by dissipating heat into the environment. Importance of Led aluminum radiator: Temperature influence, LED life may be reduced by more than 50% for every 10°C increase in junction temperature. Luminous efficiency is maintained, high temperature will cause LED luminous efficiency to decrease.

Maintain the normal operation of photovoltaic aluminum radiators or Led aluminum radiator. If e lectronic components are not properly cooled, the temperature will be too high, which will reduce the conversion efficiency and even shorten the service life. Improve Photovoltaic aluminum radiator life: Through efficient heat dissipation, the normal operation of the photovoltaic aluminum alloy profile radiator can be maintained and the service life of the equipment can be increased.

Key design parameters of Led aluminum radiator:

Thermal resistance (℃/W): The target value is usually <5℃/W. For example, a 10W LED needs to keep the junction temperature below 85°C.

When the ambient temperature is 25°C, the heat sink thermal resistance needs to be ≤6℃/W.

Surface area calculation: empirical formula, heat dissipation area (cm²) ≥ LED power (W) × 50 (under natural convection conditions).

Interface material: thermal conductive silicone grease (thermal conductivity 1-5W/m·K) or phase change material (such as graphite sheet, 5-10W/m·K).

Aluminum alloy profile

Aluminum alloy profile are the most commonly used material for LED heat sinks. Due to their advantages such as light weight, high thermal conductivity, easy processing and cost control, they are widely used in various LED lighting products. Features of aluminum alloy profile: 6063 Excellent overall performance, easy to extrude, low cost. 6061 Higher strength, but slightly more difficult to extrude. ADC12 Die-cast aluminum alloy, suitable for complex shapes, but poor thermal conductivity.

How to choose the right cooling method

Heat dissipation technologies include natural cooling, forced air cooling, liquid cooling, phase change cooling, etc., which are mainly selected according to the power of the inverter.

String photovoltaic inverters generally work in an outdoor environment above 70°C on the roof. In high temperature environments, system heat dissipation is particularly important for product performance and life. Inverters with power below 20kW can use natural cooling; while inverters with power above 25kW are more suitable for forced air cooling.