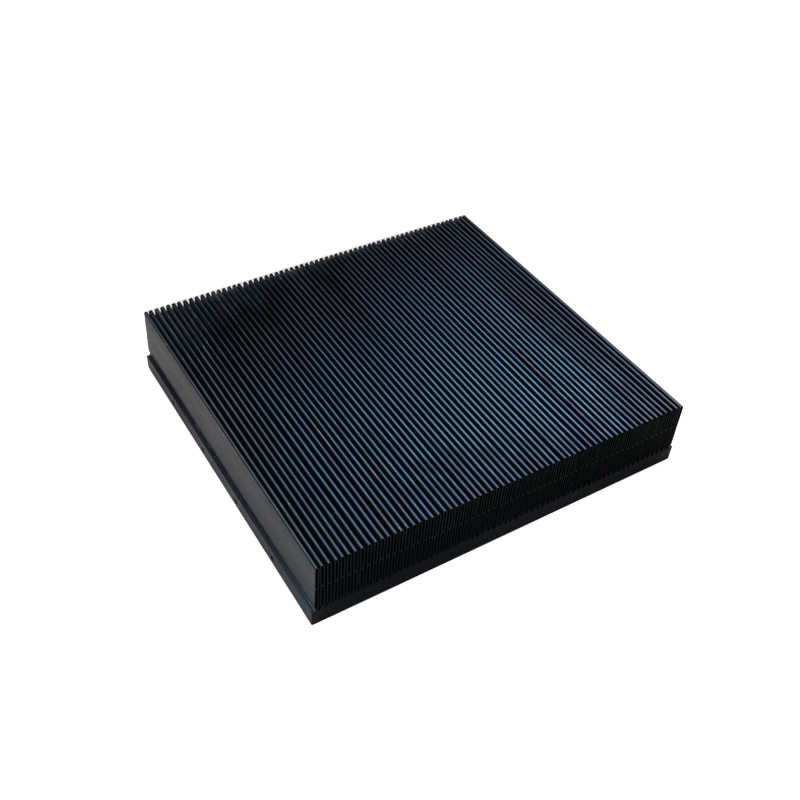

Lamp Heat Sinks Or Power Supply Radiators

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Effectively reduce the operating temperature inside the rectifier and extend the service life of the device.

Adopt lamp radiator heat sink parts, which has high safety performance in high humidity conditions.

Power supply radiator or heat conduction

Power supply radiator or heat conduction

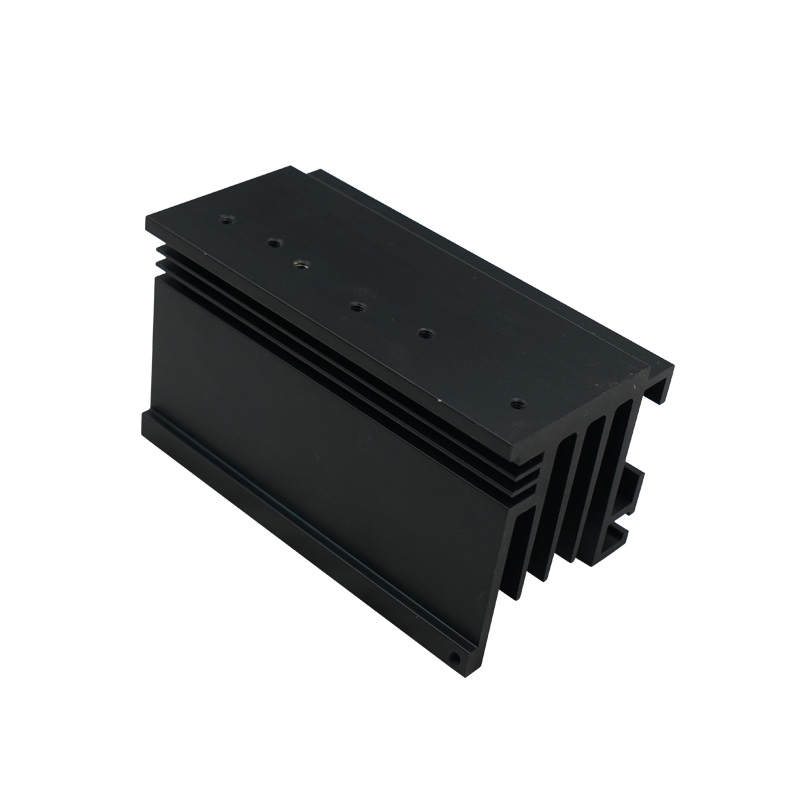

The core function of the power supply radiator: It is mainly used to solve the temperature rise problem caused by the heating of power components in electronic equipment such as PC power supplies and industrial power modules, ensuring that the junction temperature of the device remains within a safe range, usually ≤100°C, thereby improving reliability and life.

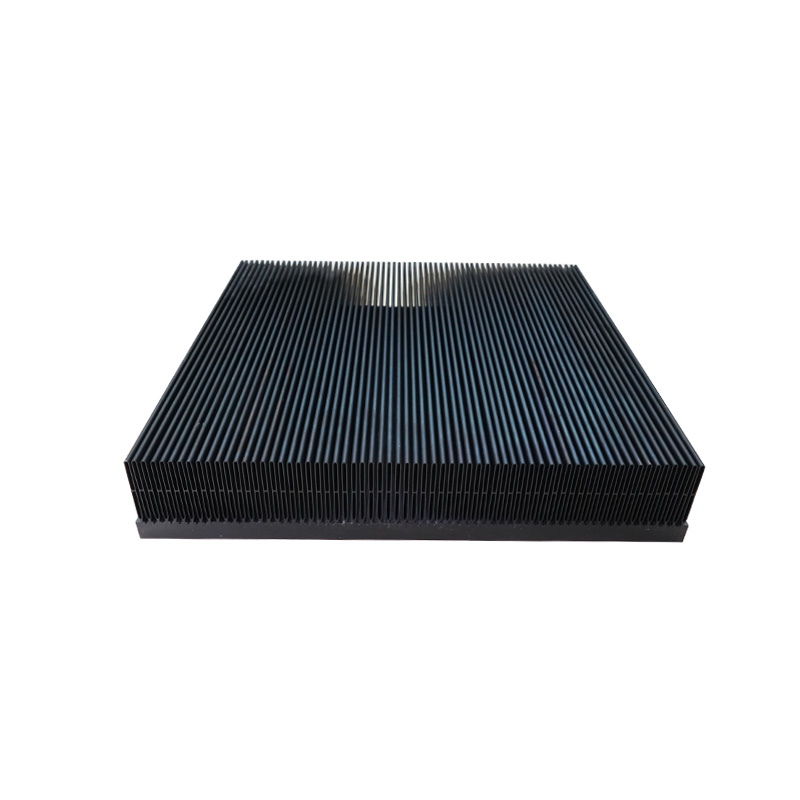

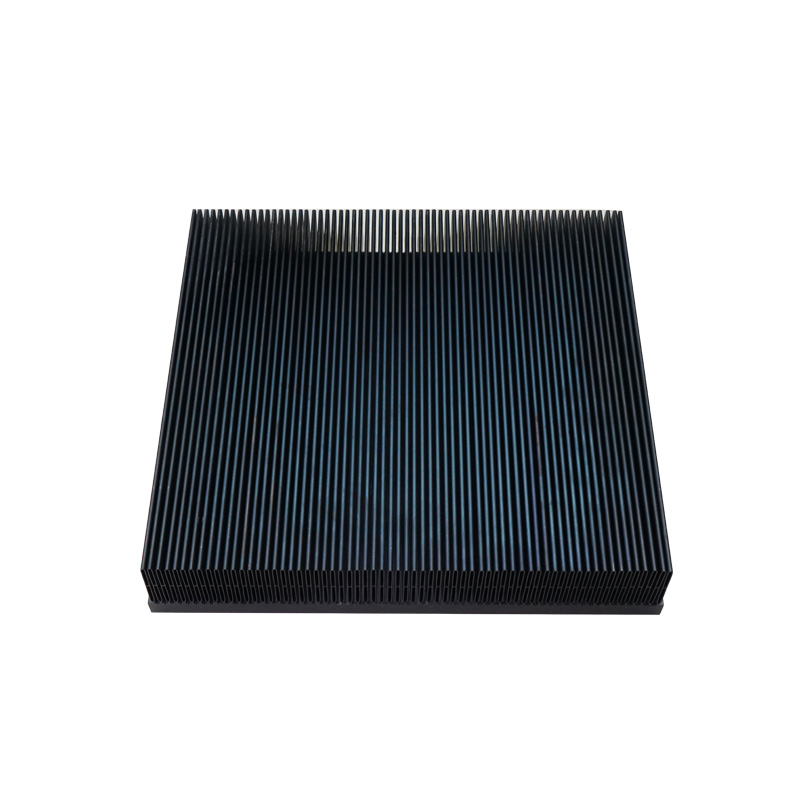

Power supply radiator refers to the heat dissipation conducted by some metal products with good thermal conductivity. The most commonly used ones are aluminum alloy radiators, which are made into a groove-shaped appearance to increase the contact area with the air. At present, this heat dissipation method is basically used when using power modules, especially high-power power modules must be equipped with heat sinks.

Heat conduction is a common way of heat dissipation, mainly through the device core, device shell, heat sink, radiator, and surrounding air. High-power power modules are generally potted and have aluminum substrates, and the lamp radiator heat sink parts are generally installed close to the aluminum substrate.

Power supply radiator structure design

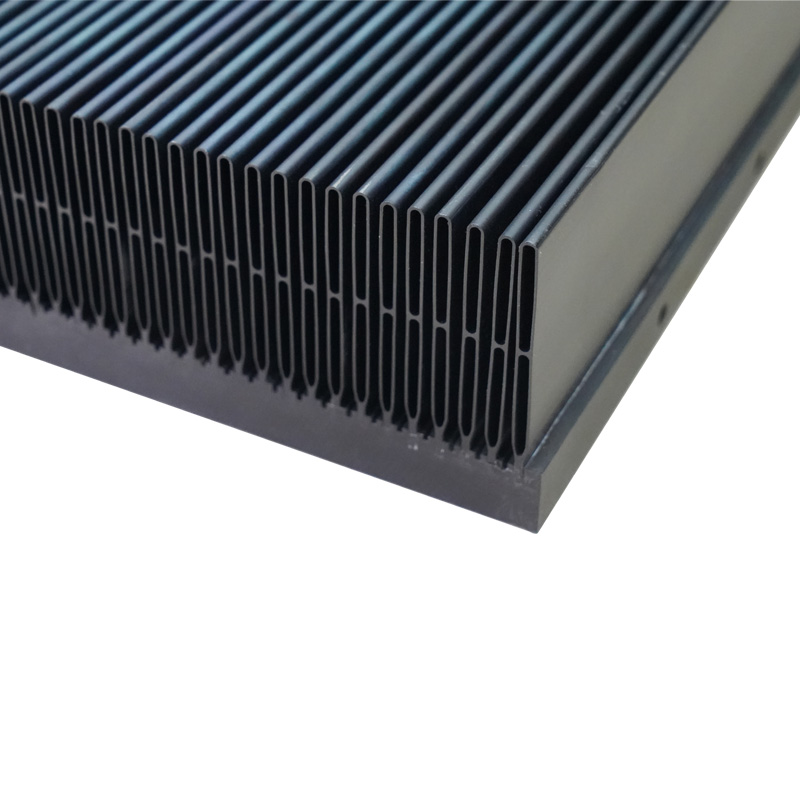

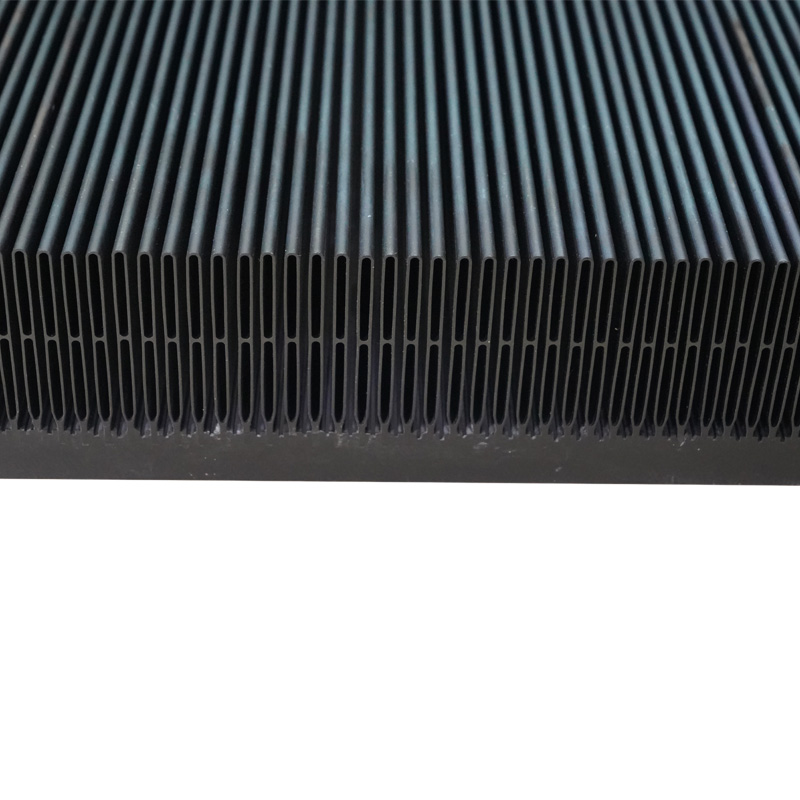

Profile radiator: manufactured through extrusion process, common fin forms include rectangular, trapezoidal or wavy to increase the heat dissipation area.

Interdigital radiator: suitable for natural convection heat dissipation, but occupies a large space.

Combined heat dissipation: such as aluminum heat sink + copper column, copper conducts heat quickly and takes away heat, while aluminum expands the heat dissipation area.

As for switching power supplies, since there is no aluminum substrate and a large heat sink cannot be installed, most of them use air cooling to dissipate heat. However , high-power switching power supplies will also arrange some power supply radiator around the power devices with high heat generation to conduct heat dissipation.

Lamp radiator heat sink parts

Lamp radiator heat sink parts is a key component used for heat dissipation in lamps and LED lamps. Its function is to quickly dissipate the heat generated by the lamp when it is working to the surrounding environment by increasing the heat dissipation area and optimizing heat conduction, thereby avoiding the decrease in light efficiency, shortened life or damage caused by high temperature.

Lamp radiator heat sink parts common materials and properties

| Material | Thermal conductivity (W/m·K) | Features |

| Aluminum alloy** (6063, etc.) | 150-200 | Lightweight, low cost, easy to process, occupy the mainstream market. |

| Copper | 400 | Optimal thermal conductivity, but heavy weight, high cost, mostly used in local key heat dissipation areas. |

| Ceramic** (AlN, etc.) | 150-200 | Insulation, high temperature resistance, but high brittleness, suitable for special high-power lamps. |

| Composite materials | Variable | Good thermal conductivity but high cost, mostly used in high-end fields. |