Fitness Equipment Aluminum 6063 Extrusions Applications

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Silicon-induced corrosion in aluminum 6063 extrusions applications is completely preventable and controllable.

Aluminum extrusions applications are ideal for forming and shaping metal from billet segments.

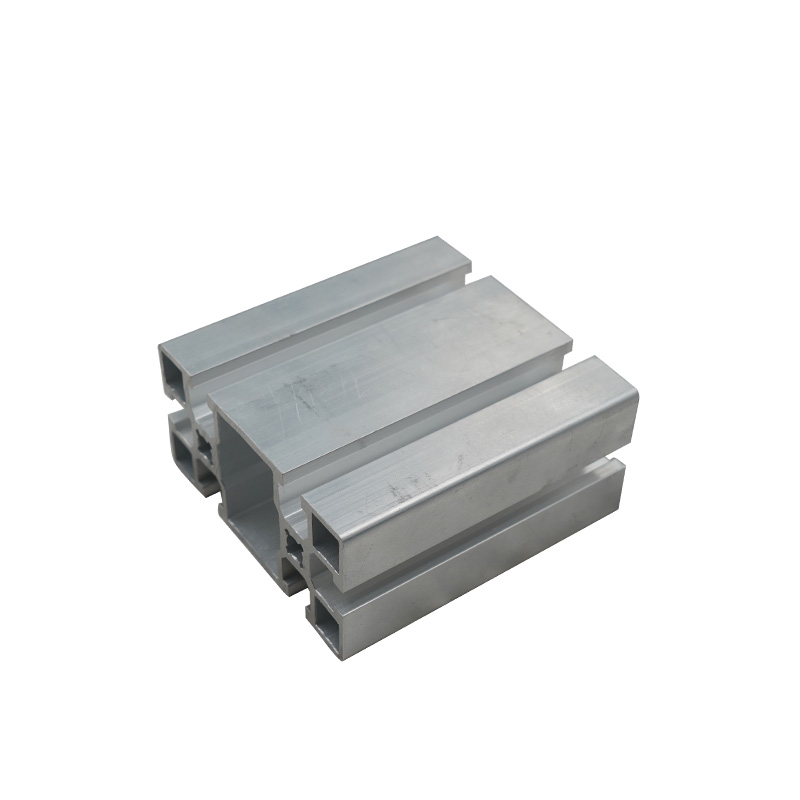

Aluminum 6063 extrusions applications

Aluminum 6063 extrusions applications

In order to ensure that doors, windows and curtain walls have high wind pressure resistance, assembly performance, corrosion resistance and decorative performance, the requirements for the comprehensive performance of aluminum alloy profiles are much higher than the industrial profile standards. Within the composition range of aluminum 6063 extrusions applications specified in the national standard GB/T3190, different values of chemical composition will result in different material properties. The chemical composition of aluminum extrusions applications has become the most important link in the production of high-quality aluminum alloy building profiles.

Performance Impact: Aluminum 6063 extrusions applications is a heat-treatable strengthened alloy with medium strength in the AL-Mg-Si system. Mg and Si are the main alloying elements. The main task of optimizing the chemical composition is to determine the percentage content (mass fraction, the same below) of Mg and Si.

ASTM Standards for 6063 Aluminum

| ASTM Standards | Description |

| ASTM B361 | Aluminum casting standards |

| ASTM B345 | Seamless aluminum tube standard |

| ASTM B491 | Aluminum Alloy Pipe Standards |

| ASTM B429 | Aluminum Pressure Vessel Standards |

| ASTM B483 | Rolled Aluminum Bar Standards |

| ASTM B210 | Aluminum Alloy Bar Standards |

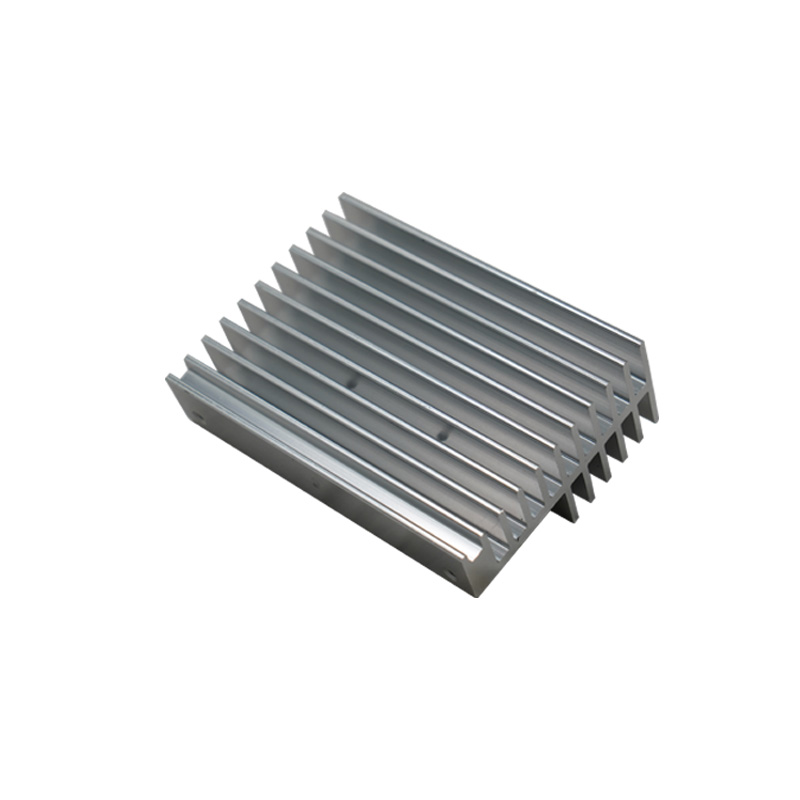

Aluminum profile used in Fitness equipment extrusions

Aluminum extrusion parts for fitness equipment are parts made by aluminum alloy extrusion process and are widely used in various fitness equipment, such as treadmill frames, strength training equipment, spinning bikes, elliptical machines, etc. Aluminum alloy has become an ideal material for fitness equipment manufacturing due to its light weight, high strength, corrosion resistance and easy processing.

Main applications of fitness equipment extrusions : Treadmill frames, providing a stable support structure and reducing the weight of the entire machine. Strength training equipment, barbell racks, etc. use high-strength aluminum profiles to ensure load-bearing safety. Spinning bikes/elliptical machines: aluminum extrusions are used for pedal brackets that are both beautiful and durable. Adjustable parts, height-adjustable seats, armrests, etc. that take advantage of the lightweight characteristics of aluminum.

Notes on purchasing fitness equipment extrusions : Wall thickness requirements: The wall thickness of load-bearing parts is recommended to be ≥3mm to ensure a stable structure. Surface treatment: Anodizing or wear-resistant powder spraying is recommended for high-frequency contact parts. Connection method: Fitness equipment extrusions hexagon socket bolts + angle code assembly method is preferred to avoid stress concentration caused by welding.