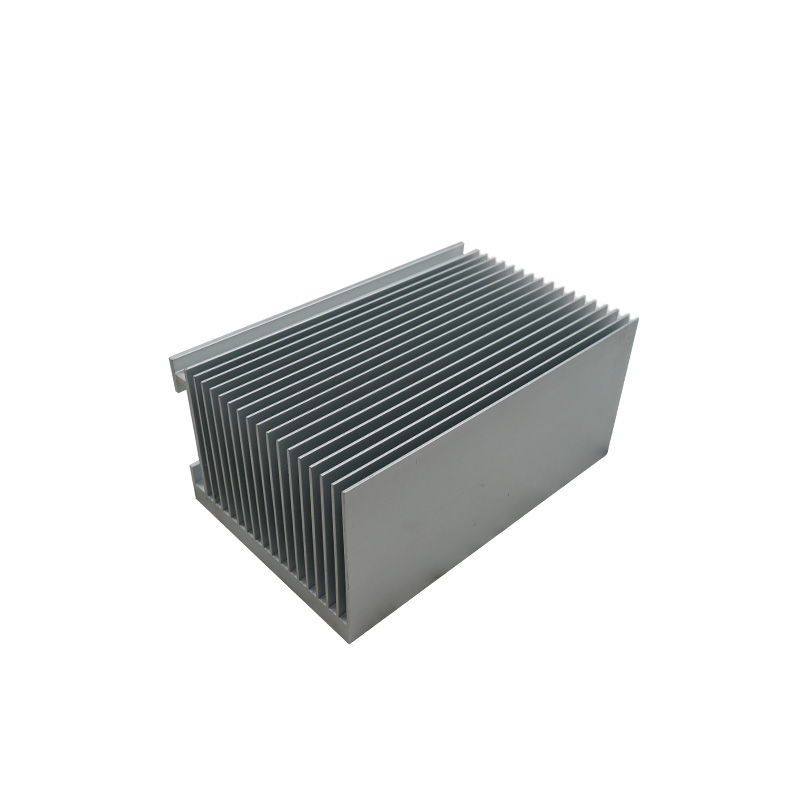

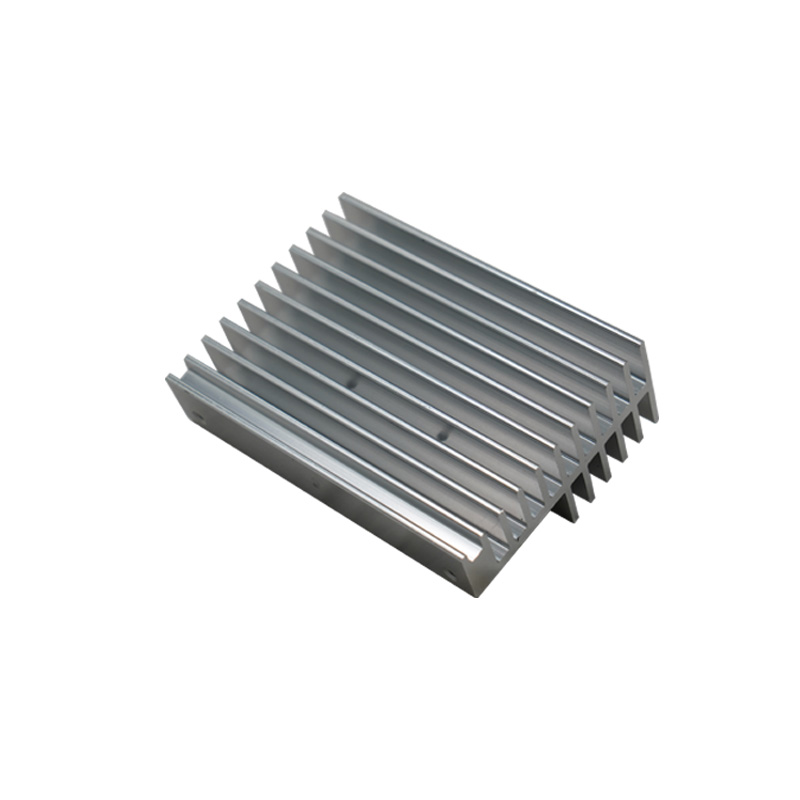

Lamp Or Chandelier Heatsink Aluminum Alloy Extrusions

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Aluminum alloy extrusions have good thermal conductivity and relatively low cost.

Lamp extrusion parts have stable performance and high cost performance.

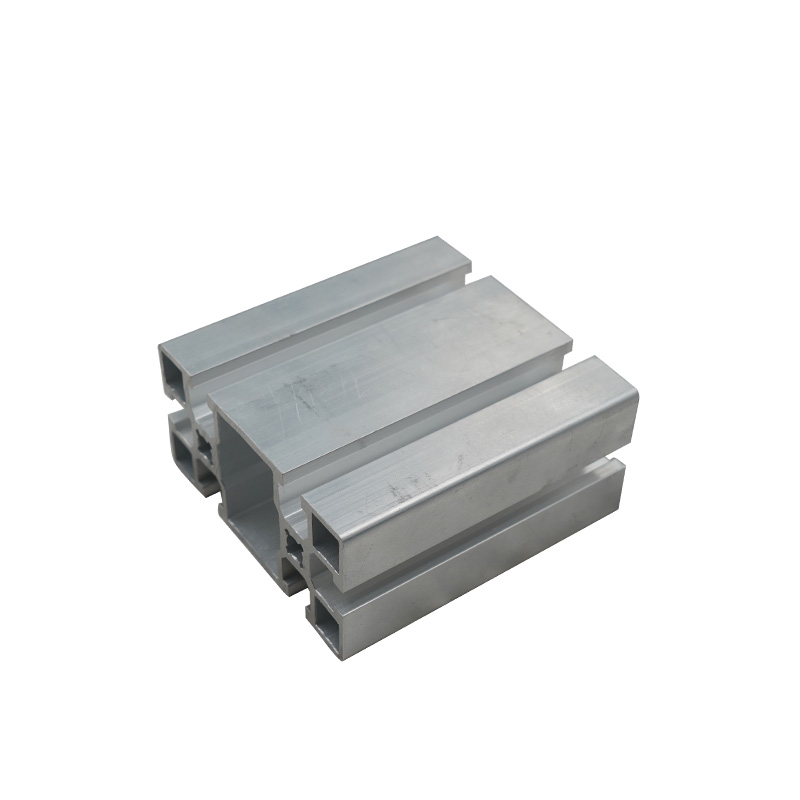

Application of Aluminum alloy extrusions

Application of Aluminum alloy extrusions

Building Products Industry

Unlike steel, aluminum alloy extrusions can be extruded into complex designs and manufactured to meet stringent building product specifications, which has helped drive its use in many residential and commercial building products. From windows, doors, atriums and skylights, to ramps, balconies and various roof designs, Lamp extrusion parts or chandelier heatsink extrusions, architects are turning to aluminum to create green, sustainable buildings that will stand the test of time.

Consumer Goods Industry

Since aluminum extrusions were first introduced in washers and dryers, it has revolutionized the home appliance market, making air conditioning systems and refrigerators more energy efficient than ever before. Today, aluminum alloy extrusions are used in many of our everyday items, including fitness and sports equipment and furniture and lamp extrusion parts or chandelier heatsink extrusions.

Electronics Industry

Today, extrusions aluminum alloy are used in many electrical and electronic devices. Given their unique electrical and thermal conductivity, custom aluminum extrusions are often used for motor housings, high heat sinks, and internal frames. In some cases, complete product housings are designed with Aluminum extrusions, which can be found in many laptops, Apple iPhones and iPads, and HDTVs.

Lamp extrusion parts

The lamp extrusion parts needs to clarify the type of lamp required, confirm whether it is an LED lamp, fluorescent lamp or other type. Different lamps have different requirements for the heat resistance and light transmittance of the extrusion. Clarify the functional requirements: Is the extrusion used to fix the lamp, dissipate heat, protect or connect it。

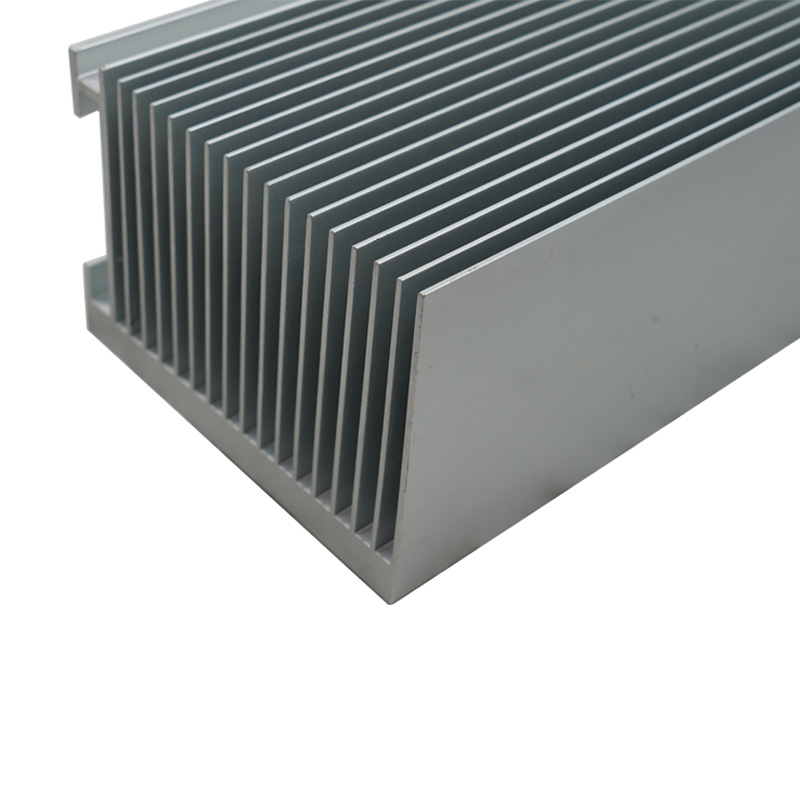

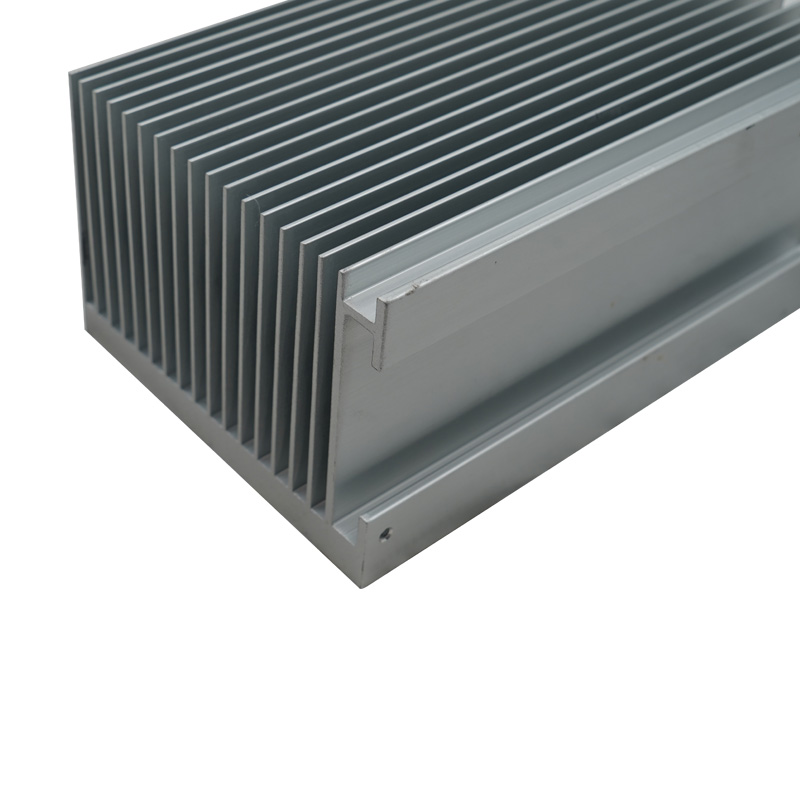

Key points of lamp heat sink extrusion process: Metal extrusion, mold design, lamp tube shape and installation slot must be considered. Tolerance is controlled within ±0.1mm to ensure assembly accuracy. Post-processing such as spraying, electroplating or thermal conductive coating (LED heat sink). UV stabilizer needs to be added to the material to prevent yellowing when used outdoors. A snap-on structure can be designed to reduce subsequent assembly processes.

Chandelier heatsink extrusions

Analysis of the core requirements of the chandelier heatsink extrusions: Ensure that the junction temperature of the LED light source or high-power bulb is controlled within a safe range, usually ≤85°C, to extend the life. The chandelier has a complex structure, multiple branches, and strong decorativeness, and needs to balance the heat dissipation efficiency and aesthetics.