Building Aluminum Profile Radiator

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Aluminum profile radiators have good heat dissipation performance.

Building aluminum profile also have the characteristics of energy saving.

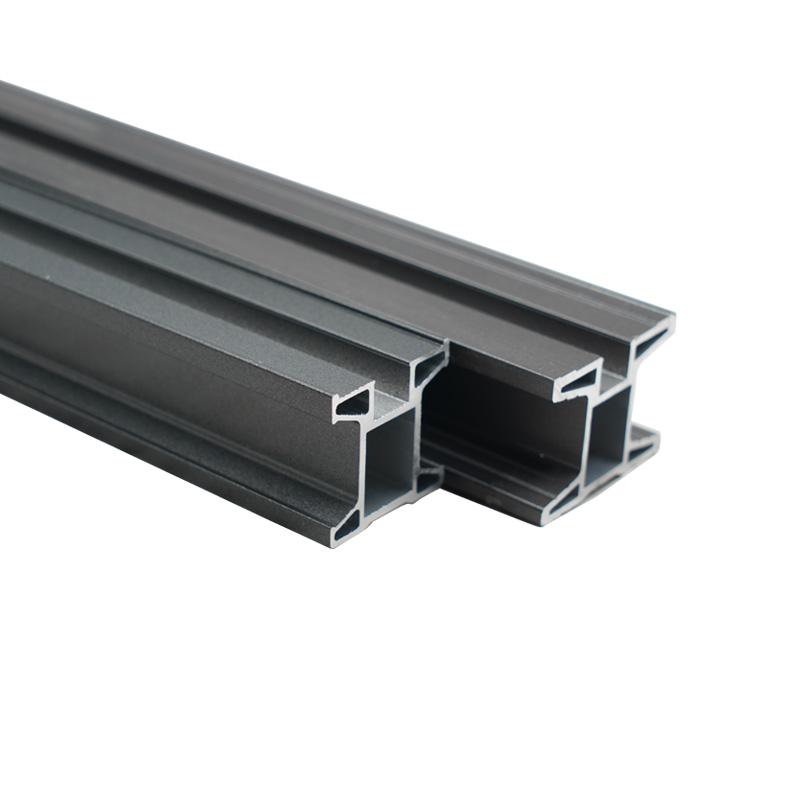

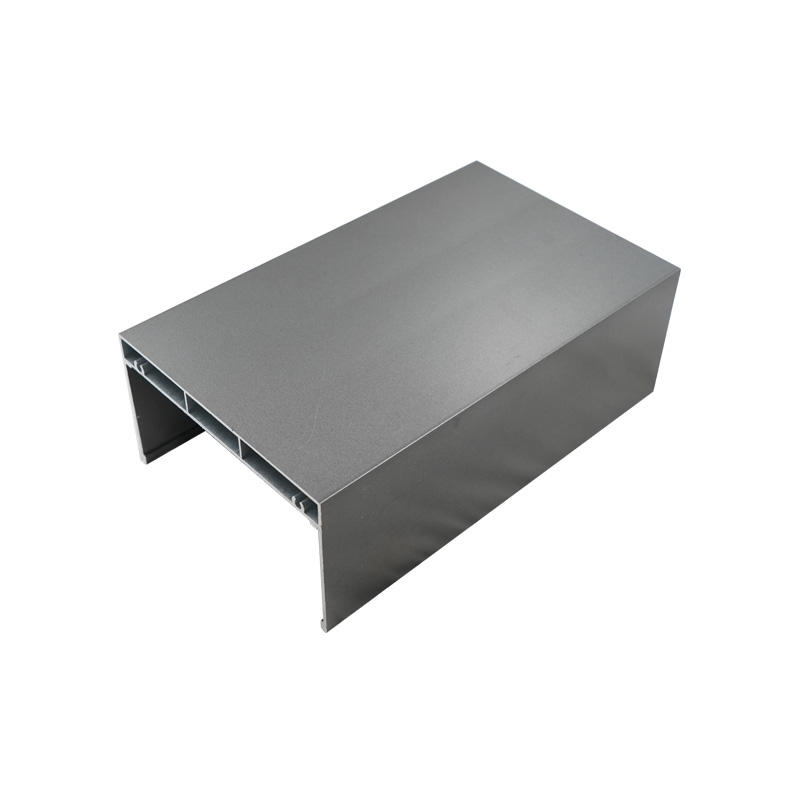

Building aluminum profile

Architectural aluminum profiles, aluminum alloy profiles used in buildings. They have the advantages of environmental protection, high strength, and diversified processing. Future development trends: Casting green buildings, responding to national calls, launching energy-saving aluminum profiles, and widely using photovoltaic integrated design profiles. Smart furniture doors and windows. Gradually developing architectural aluminum profiles with 3D printing technology, and processing of special-shaped aluminum profiles.

When it comes to building aluminum profile, factors such as UV resistance, weather resistance and aesthetic appeal should be taken into consideration. Therefore, we can help you make a more reliable choice. Trust our professionalism.

Main categories of architectural aluminum profiles(Building aluminum profile)

Classification by use: casement windows, sliding windows, curtain walls and other window and door profiles; unitized curtain walls, framed curtain walls; decorative profiles such as edging, ceilings, railings; structural profiles such as canopies and overpasses; special profiles such as sound insulation and fire protection.

Classification by alloy model: 6063-T5, easy to extrude, good surface treatment performance; 6061-T6, high-strength load-bearing structure, good weldability; 6005A, strong comprehensive performance; 3003, corrosion-resistant, easy to process.

Advantages of architectural aluminum profiles: density 2.7g/cm³, lightweight. 6061-T6 tensile strength ≥240MPa, high strength. Oxide film protection, long life. Recycling rate >95%, green and environmentally friendly. Can be processed by CNC, cutting, etc.

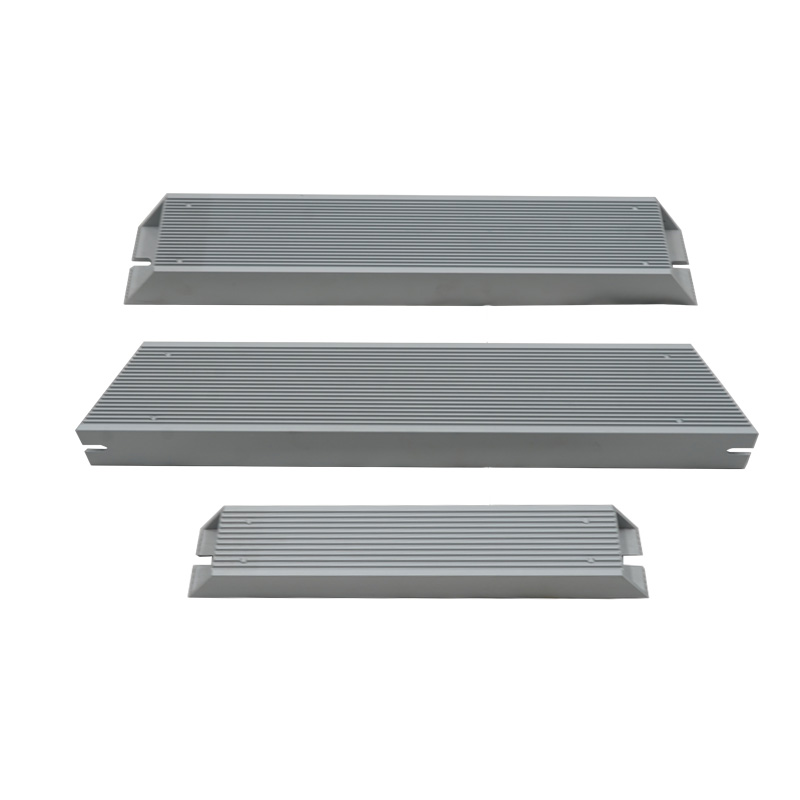

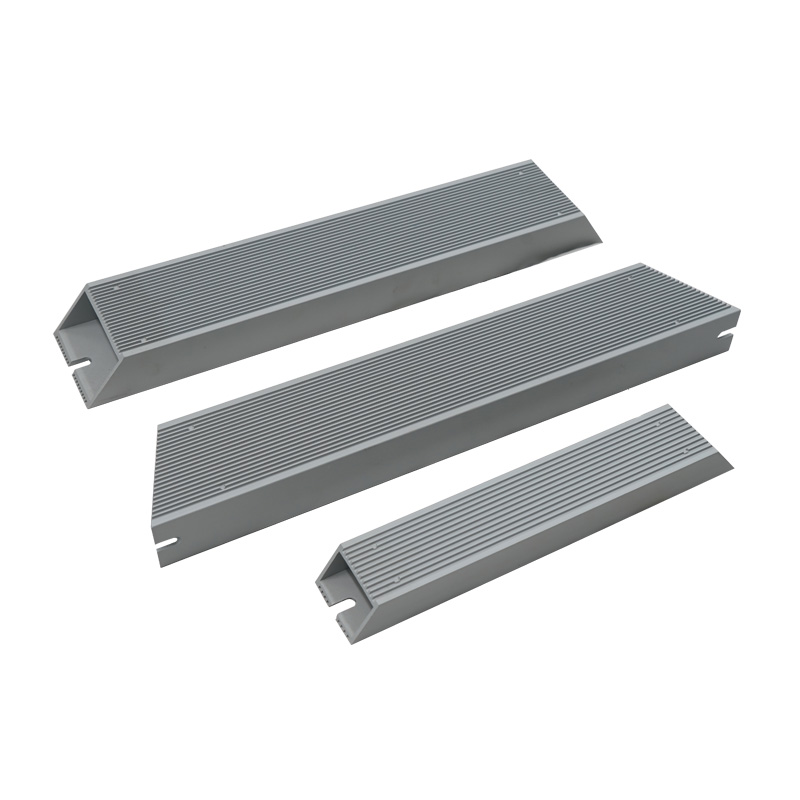

Aluminum profile radiator

Common aluminum profile radiator material and alloy selection

| Alloy model | Thermal conductivity (W/m·K) | Features | Applicable scenarios |

| 6063 | About 200 | Low cost | LED heat sink |

| 6061 | About 170 | Higher strength | electronic equipment |

| ADC12 | About 96 | Die casting | Complex shape heat sink |

| 1050 | 约230 | Pure aluminum | Precision heat sink |

Aluminum profile radiator structure design type

1. Extruded heat sinks are formed by extrusion of molds. Typical structures include fin type and sunflower type. The fin height is generally ≤150mm.

2. The skived heat sink is processed by CNC to achieve ultra-thin fins with a thickness of up to 0.3mm.

The high fin density can achieve high power heat dissipation efficiency, such as CPU servers.

3. Die-cast heat sink, three-dimensional structure, integrated mounting holes.

4. Combined radiator, combining copper and aluminum fins. Copper has excellent thermal conductivity and aluminum radiator has a large heat dissipation area.