Aluminum Active Or Passive Extruded Heat Sinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Suitable for electronic components.

Based on the principle of natural or unnatural air flow heat dissipation.

Aluminum Active Or Passive Extruded Heat Sinks

The vital role of the heat sink is to dissipate heat from electronic components.

Depending on the customer's application, decide which heat sink is most suitable - passive or active heat sinks.

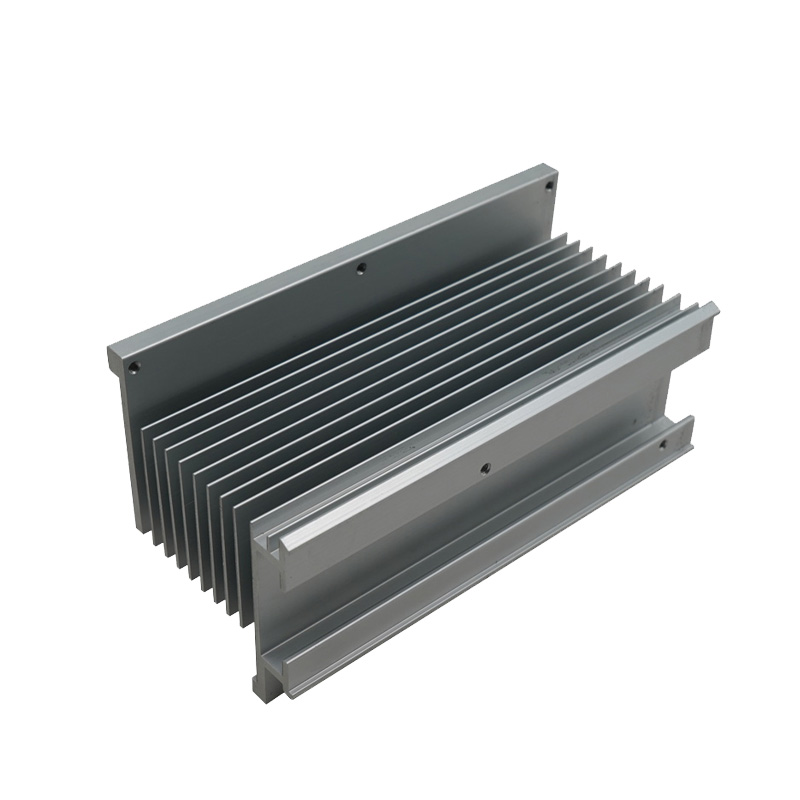

Extruded Heat Sinks Design Features

Fin density: High-density fins can increase the heat dissipation area of the extruded heat sinks, and pay attention to balancing the air flow resistance.

Substrate thickness: make sure extruded heat sinks is in contact with the heat source area (such as CPU, power device) and reduce thermal resistance.

Natural convection vs forced air cooling: Natural convection relies on the 5-10mm spacing between the fins and the vertical effect of placement. Forced air cooling can be designed with fins that are denser and extruded heat sinks uses a fan to dissipate heat.

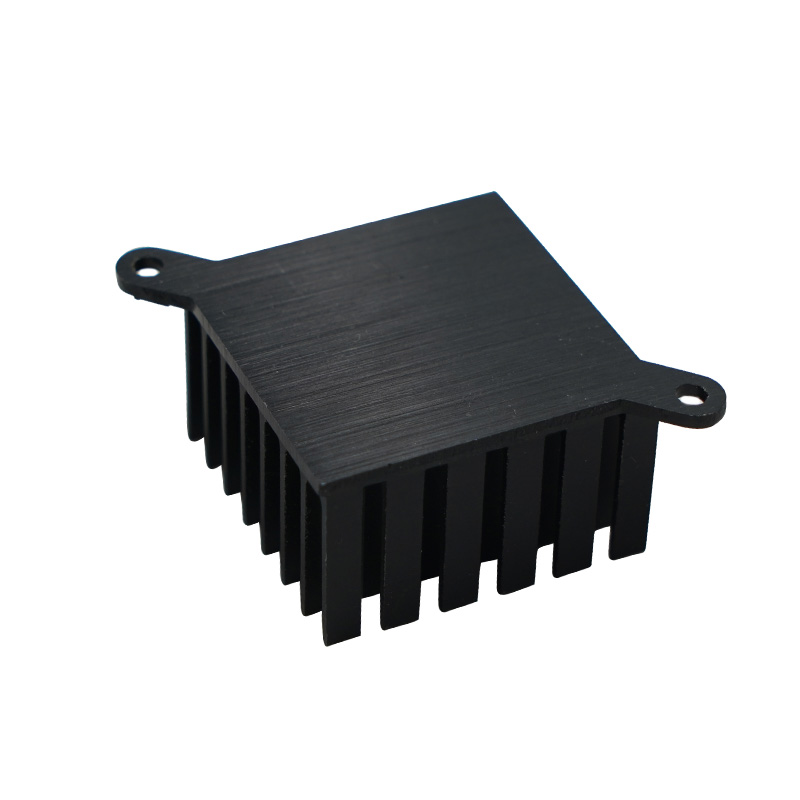

Aluminum Active Heat Sinks

Aluminum Active Heat Sinks Typical design parameters | ||

Parameter | Typical value/range | Illustrate |

| Fin height | 10-50mm | Too high, increase fan pressure |

| Fin spacing | 1.5-3mm (forced air cooling) | Natural convection requires ≥5mm |

| Fan air volume | 0.5-5 CFM (small size) | High power consumption devices, more than 10 CFM |

| Thermal resistance (overall) | 0.5-3℃/W | Contact thermal resistance and fan performance affect the overall |

1. Aluminum Active Heat Sinks to enhance heat dissipation, use a fan or blower.

2. Active Heat Sinks can provide efficient cooling under high heat loads.

3. Aluminum active heat sinks is suitable for electronic equipment in small spaces or temperature-sensitive equipment and has good temperature control capabilities.

4. High power, loud noise,high performance.

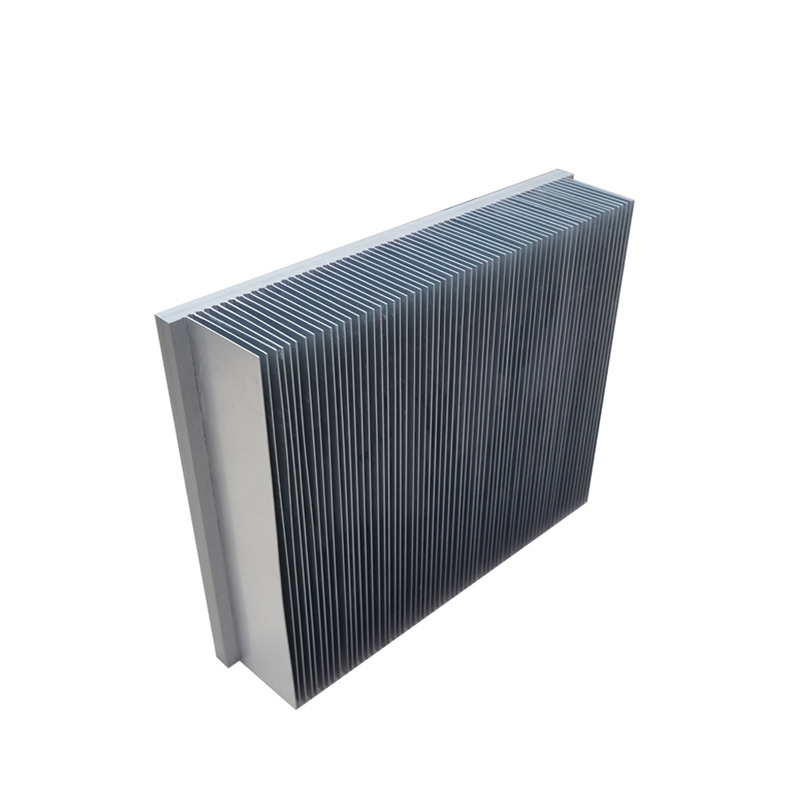

Passive heat sinks

Passive heat sinks Typical structural parameters | ||

| Parameters | Recommended range | Design basis |

| Fin height | 10-100mm | Not too high to ensure structural strength |

| Fin thickness | 1-3mm | Not too thin, as too thin will result in insufficient heat capacity |

| Substrate thickness | 3-15mm | Ensure thermal diffusion capacity (heat source to fins) |

| Surface treatment | Anodizing or sandblasting | ncrease emissivity to 0.8+ |

1. Passive heat sinks do not require active cooling mechanisms in the base structure and are suitable for quiet, noise-sensitive environments.

2. In addition, the main advantages of the passive heat sinks are high efficiency and energy saving, no additional power consumption, no need for moving parts, longer service life and higher reliability.

3. For high heat loads, passive heat sinks may take longer to cool down and are not suitable for applications with extreme thermal demands.