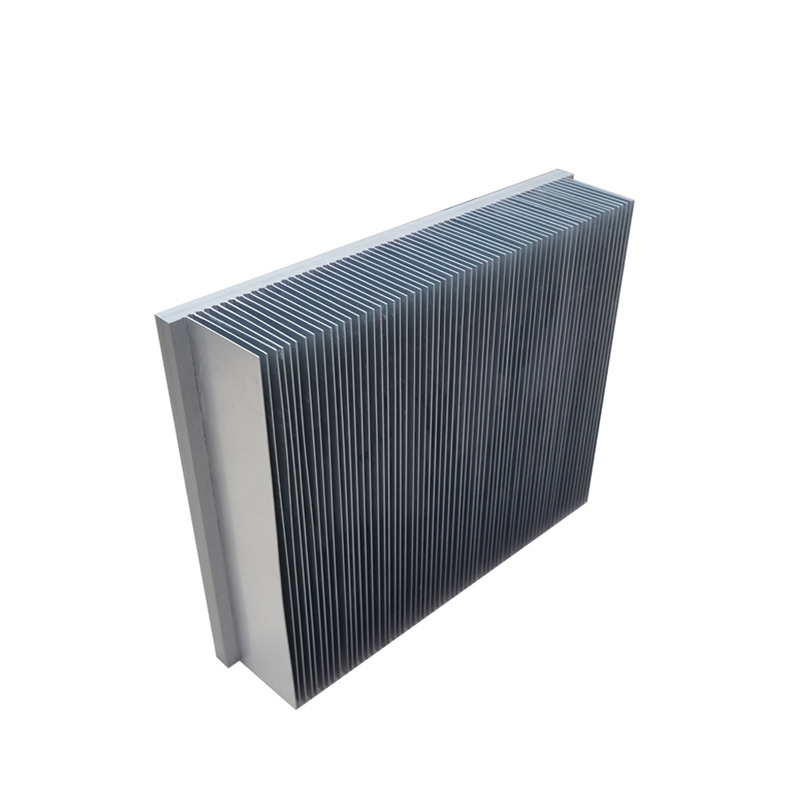

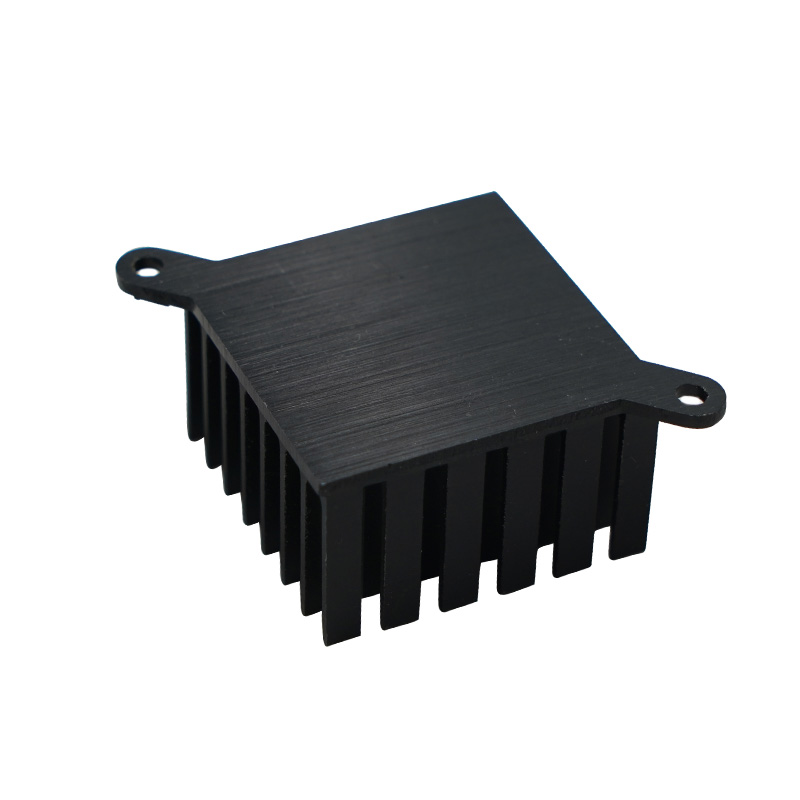

Industrial Aluminum Generator Heat Sinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

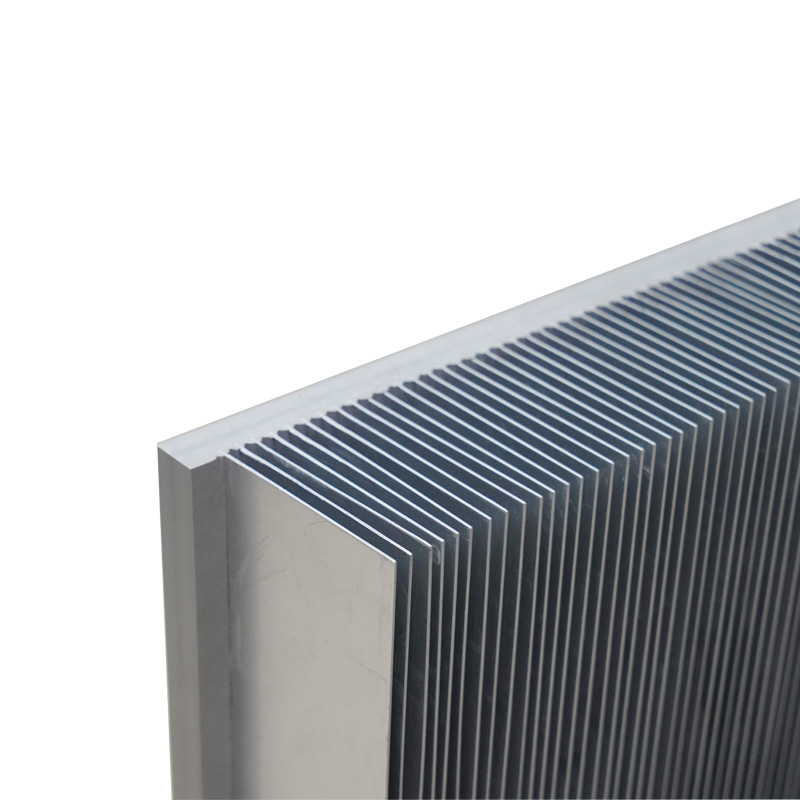

Use a material with good thermal conductivity - aluminum.

Diversified application fields of Industrial heat sinks.

Application areas of industrial aluminum profile radiators

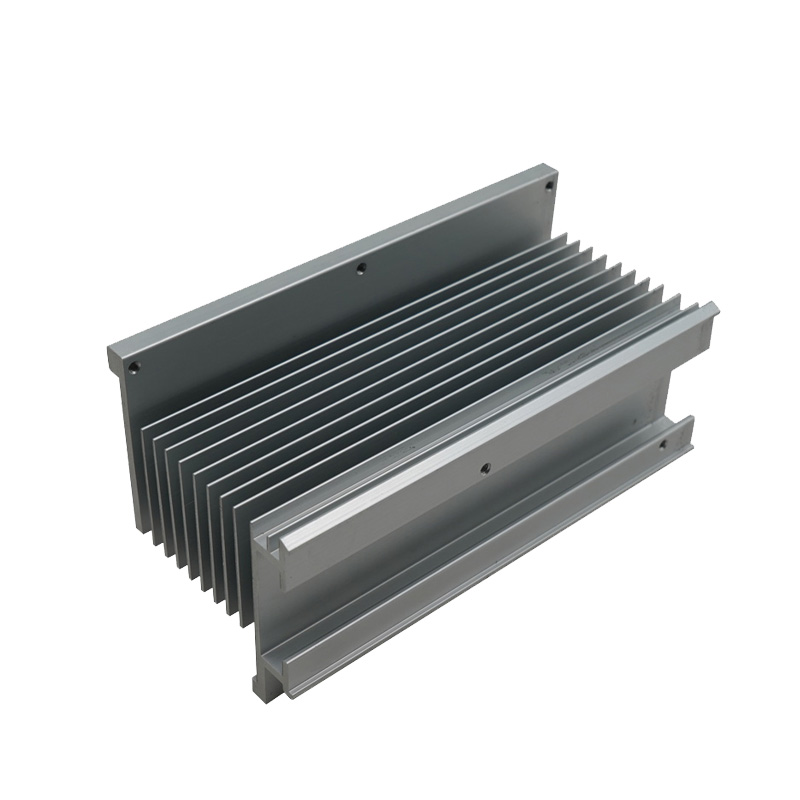

Industrial heat sinks are widely used in cooling systems in various industries, such as electronic equipment, machinery manufacturing and energy industries.

In the field of machinery manufacturing, industrial aluminum profile radiators are used in cooling systems, such as engine cooling, transmission cooling, etc. In the field of electronic equipment, it is used to dissipate high-power electronic components, such as power supplies, inductors, transformers, etc. In the energy industry, it is used in the cooling systems of thermal power plants and nuclear power plants to ensure the normal operation of equipment.

Comparison of aluminum and copper Industrial heat sinks:

| Comparison | Aluminum heat sink | Copper heat sink |

| Thermal conductivity | Higher (195-220 W/(m·K)) | Higher (about 400 W/(m·K)) |

| Weight/Cost | Lightweight/Lower Cost | Heavier/high cost |

| High temperature resistance | Suitable for medium and low temperatures (<200°C) | High temperature resistance (>270°C) |

| Corrosion resistance | Surface treatment required ,such as anodizing | Naturally corrosion-resistant |

Aluminum industrial heat sinks has light weight, good heat dissipation effect and low cost.

Compared with traditional copper heat sinks, aluminum industrial heat sink more attention is paid to improving the heat dissipation effect and reducing manufacturing costs.

Aluminum material has good thermal conductivity and can quickly conduct heat to the surface.

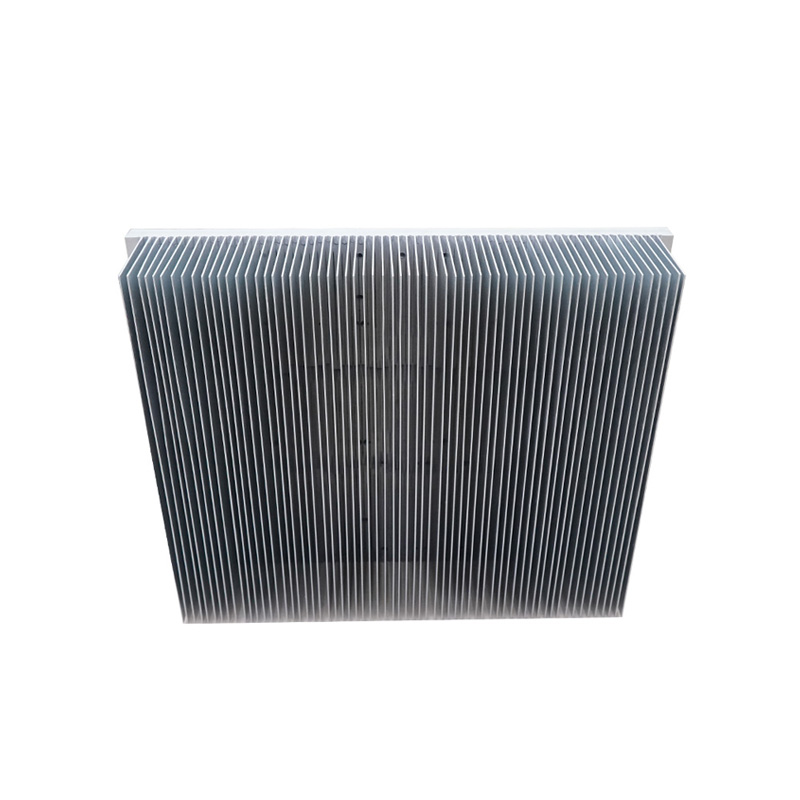

Maintenance and maintenance of industrial heat sinks: Clean the surface and remove dust and debris regularly.

Take care to prevent any form of damage that could destroy the structure and effectiveness of the Industrial Aluminum Generator Heat Sinks.

Aluminum Generator heatsink

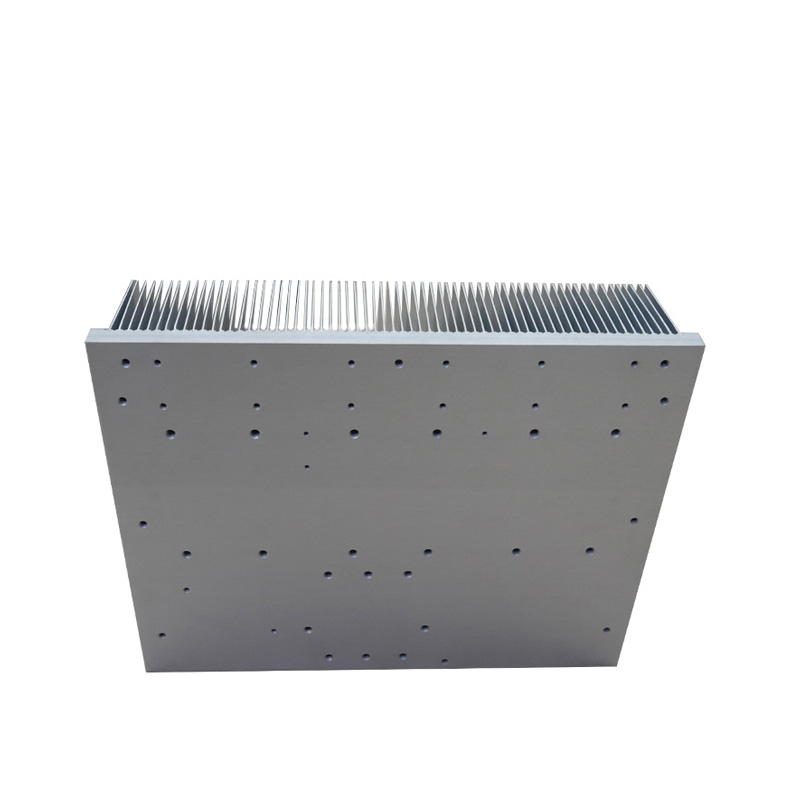

Aluminum generator heatsink are widely used in the generator field due to their light weight and good heat dissipation performance.However, in extremely high temperature or high corrosion environments, copper-aluminum composite radiators or pure copper radiators can be used. With the advancement of high thermal conductivity aluminum alloys (such as Si-Mg-Ti-B alloys with thermal conductivity of more than 195 W/(m·K)) and intelligent heat dissipation technology, the application scope of aluminum radiators will be further expanded.

Application scenarios of aluminum generator heatsink

Small and medium-sized aluminum generator heatsink sets: ordinary diesel and gasoline generators, with controllable costs.

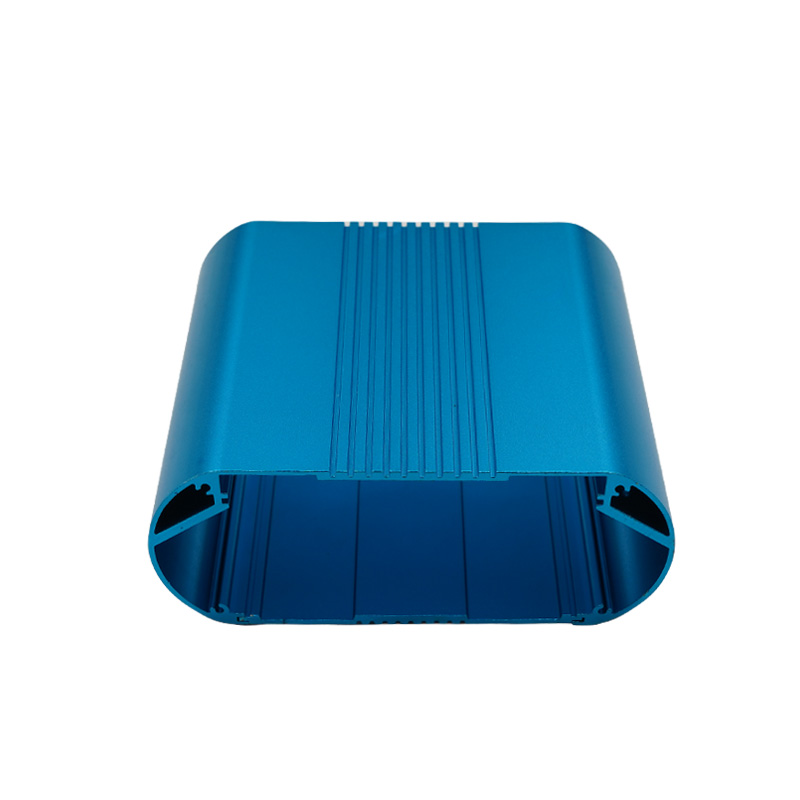

New energy field: photovoltaic inverters, aluminum radiators for wind turbines.

Automotive aluminum generator heatsink sets: lightweight on-board generators