Large Aluminum Cnc Machined Copper Heat Sinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

cnc machined heat sink involve complex geometries, maximize heat exchange area.

Copper or brass with good thermal conductivity and corrosion resistance can be used CNC copper heat sink.

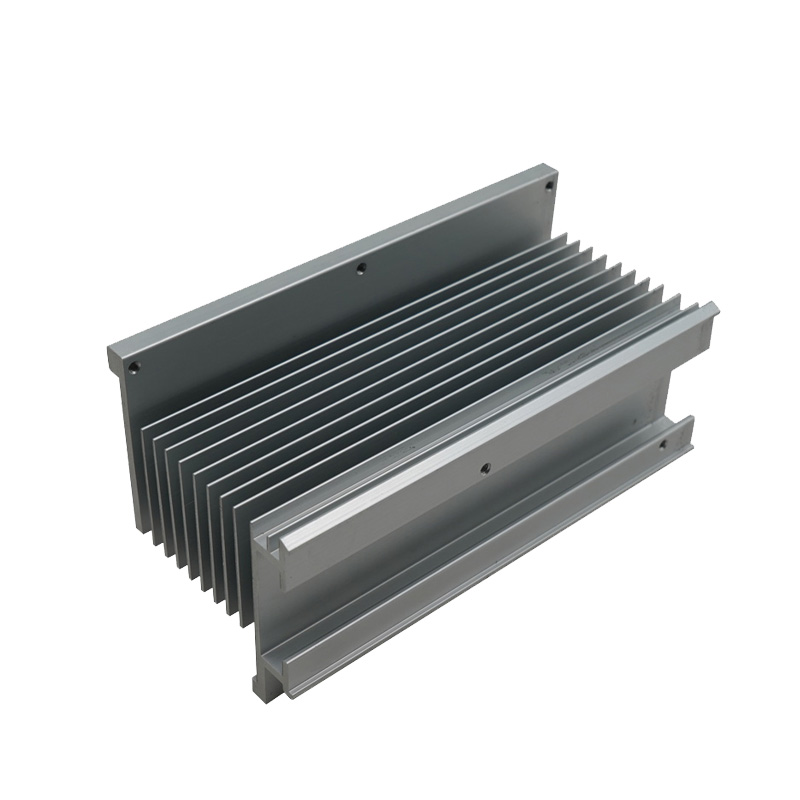

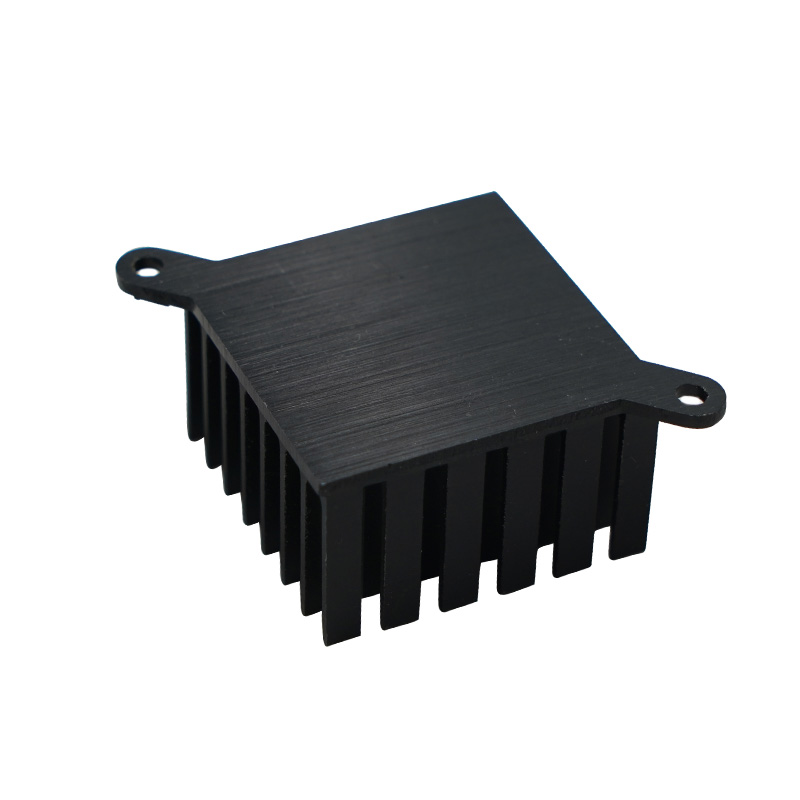

Cnc Machined Heat Sinks

| cnc machined heat sink | |

| Material | Copper ; Aluminum |

| Temper | Customized request available |

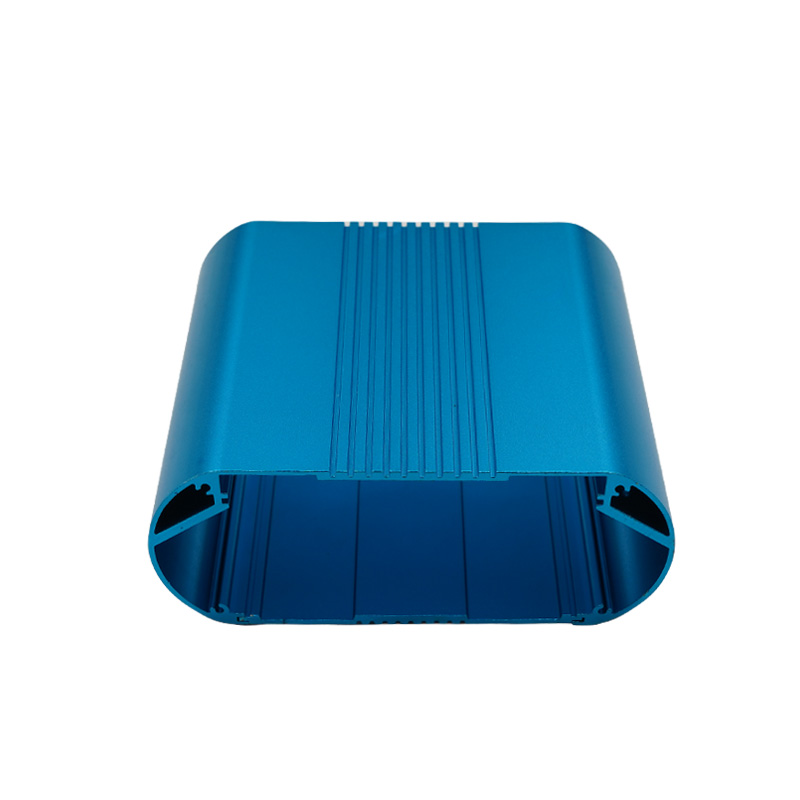

| Color | Customized colors, metallic silver, black, white, blue, etc. |

| Surface Treatment | Anodized, Powder coated, mill finish, polish, brushed |

| Certificate and Standard | ISO9001, ISO14001, IATF 16949, SGS |

| Lead Time | Die Developing and Sample testing: 15-20 days.Production: 20-30 days. |

| Payment Term | T/T30% |

| FOB Port | Qingdao, Shandong province,China |

| Packing Details | Protection film and wooden packing, or depend on clients special requirement. |

Copper heat sink

Copper heat sink: The raw material is brass or bronze, which has high thermal conductivity. The thermal conductivity of copper is about 400 W/m·K, and the thermal conductivity of aluminum is about 200 W/m·K. Copper heat sinks are often used in equipment with high requirements for heat dissipation performance.

Application of copper Heat Sink:

Electronics industry electronic products (computers, communications) to protect components from overheating.

Automotive industry: copper heat sinks dissipation of engines, gearboxes and other components to ensure the reliability of vehicles during high-load operation.

Aerospace: In aircraft and aerospace vehicles, efficient heat dissipation ensures the stability and safety of the equipment.

Industrial equipment: cnc machined heat sink, Industrial heavy machinery and equipment, maintain working temperature and extend service life.

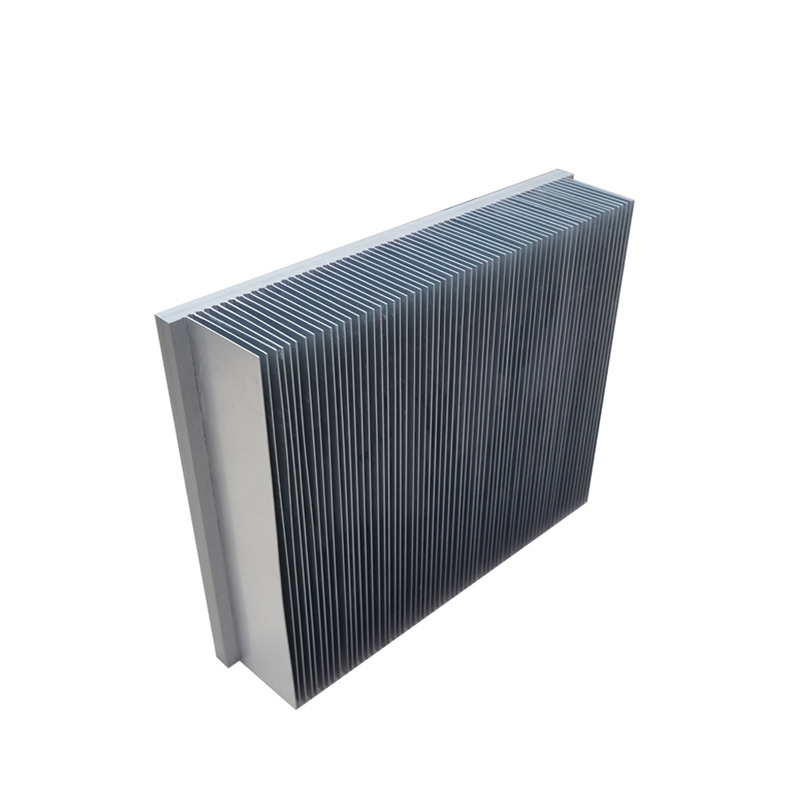

Large aluminum heat sink

Alloy Material Selection

Commonly used aluminum alloys such as 6063 and 6061 have thermal conductivity, a thermal conductivity of about 160-180 W/m·K, high mechanical strength and corrosion resistance.6063 aluminum alloy is suitable for Large aluminum heat sink material selection under normal conditions. If it is used in a high temperature or corrosive environment, it is recommended to choose an alloy material with higher strength.

Large aluminum heat sink casting process

According to the alloy ratio, the aluminum ingot is mixed with other elements such as silicon and magnesium, heated to liquid, and degassed to improve the purity of the aluminum. It is then cooled into round cast rods through a deep well casting system and then made into large aluminum heat sink.

Process development trend

Lightweight and efficient heat dissipation: Improve heat dissipation area through alloy optimization or precision cutting technology.Automated production: Introduce processes such as laser welding and automated assembly lines to improve efficiency.