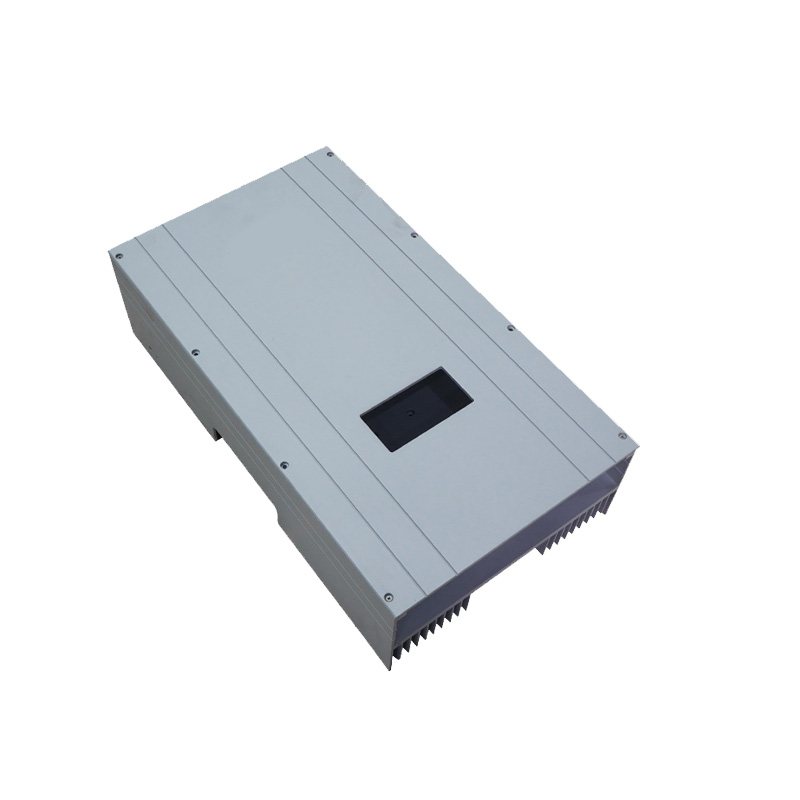

LED Light Extrusion Thermal Heat Sinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Suitable for different types of LED lighting heat sinks.

Heat sinks help LED operate more efficiently and extend their life.

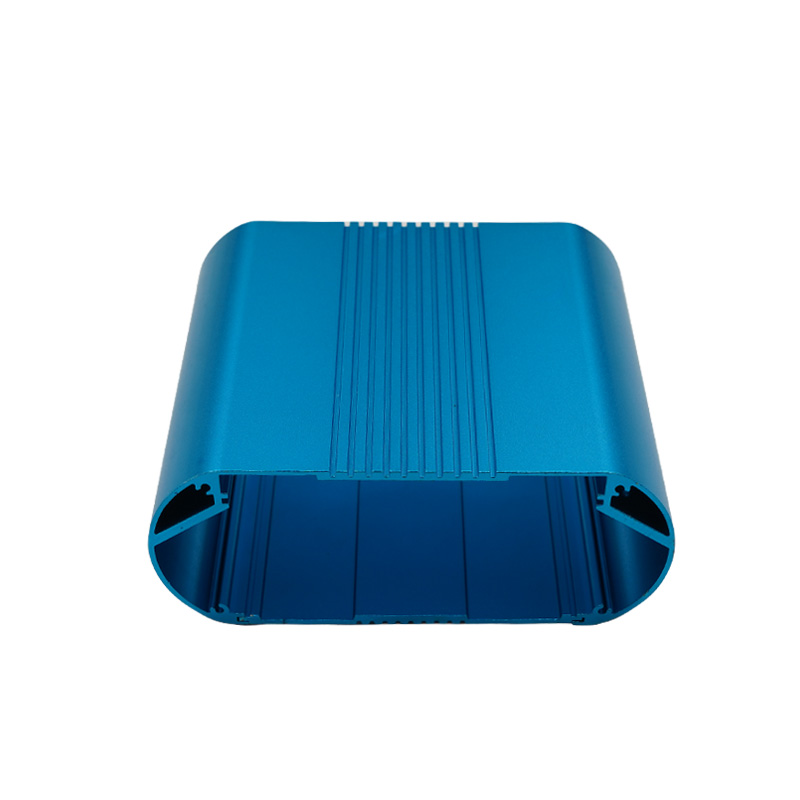

Aluminum Thermal Heat Sink can be mass produced and equipped with a variety of heat treatment technologies.

Basic principles of Aluminum LED light heat sink

The core function of the LED light heat sink is to dissipate the heat generated by the LED chip and prevent the radiator from overheating. LED heatsinks generate heat when working electrical energy is converted into light energy. If heat dissipation is poor and the temperature rises, light decay will be accelerated and the LED chip may even fail.

The design of the LED heatsinks needs to consider thermal conductivity, air flow or heat dissipation area to ensure the stable operation of the LED.

The choice of LED heatsinks depends on many factors. The options are as follows: Low-cost option, choose aluminum alloy fins for heat dissipation. High-performance option, copper-based heat dissipation, or heat pipe + fan. Under special needs, ceramic graphene can also be used as a heat dissipation material.

LED light heat sink Manufacturing process of heat sink | ||

| Process | Features | Applicable scenarios |

| Die casting | Low cost, mass production, average thermal conductivity | Ordinary LED lamps |

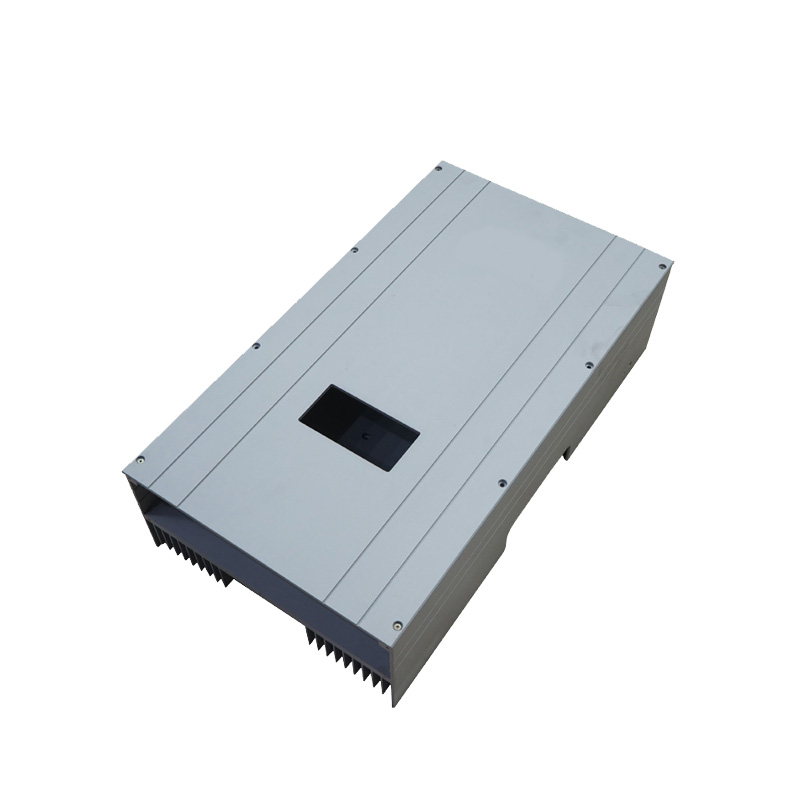

| Extrusion molding | Thin LED heatsinks fins, good thermal conductivity | Medium power LED |

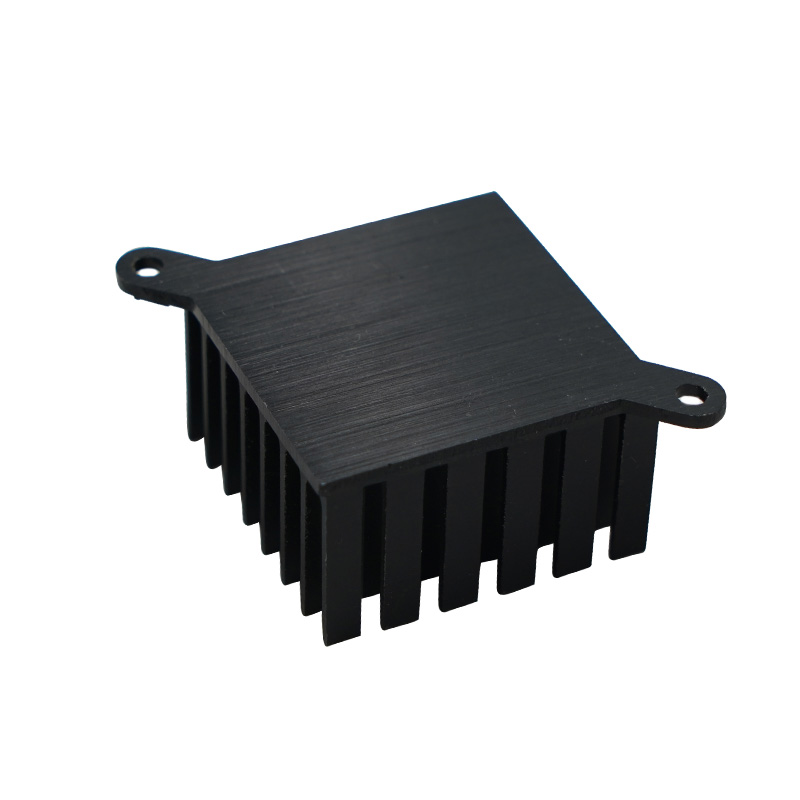

| CNC processing | High precision, high cost | High power/customized aluminum thermal heat sink |

| Stamping process | Low cost, thin LED light heat sink | Small LED module |

Structural design of LED heatsinks

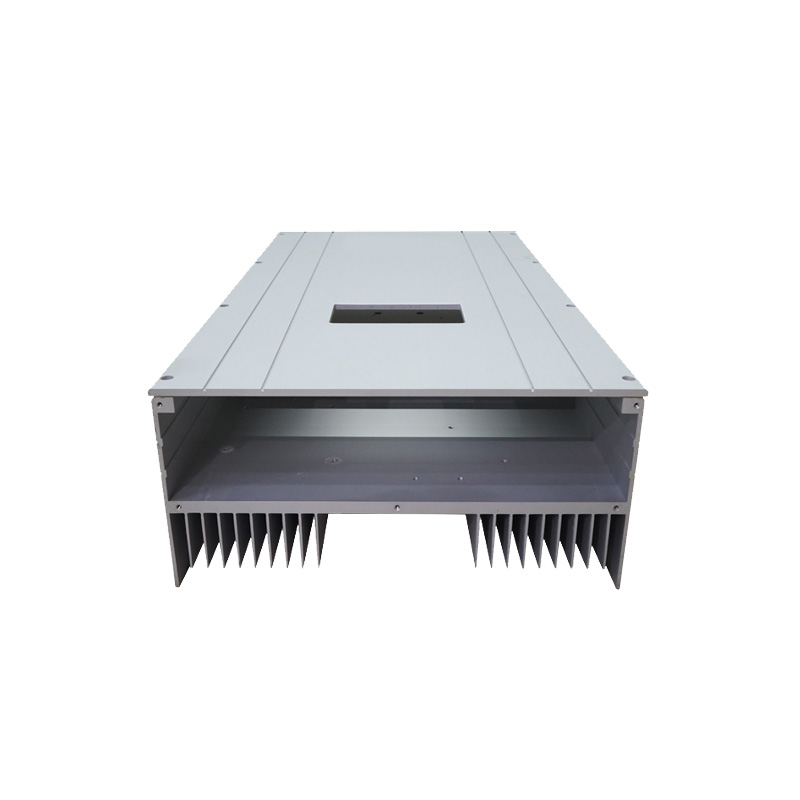

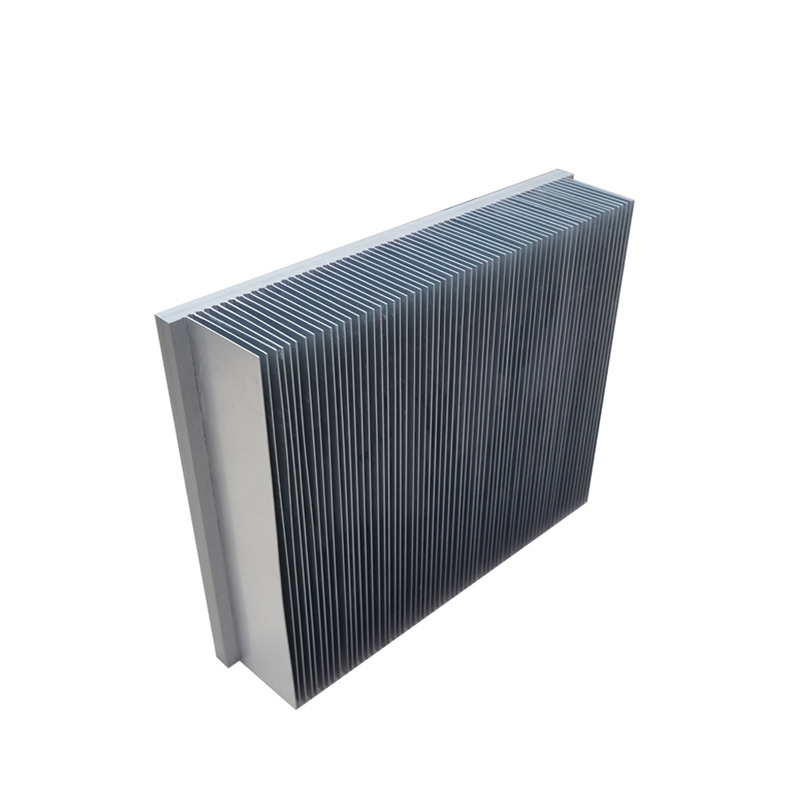

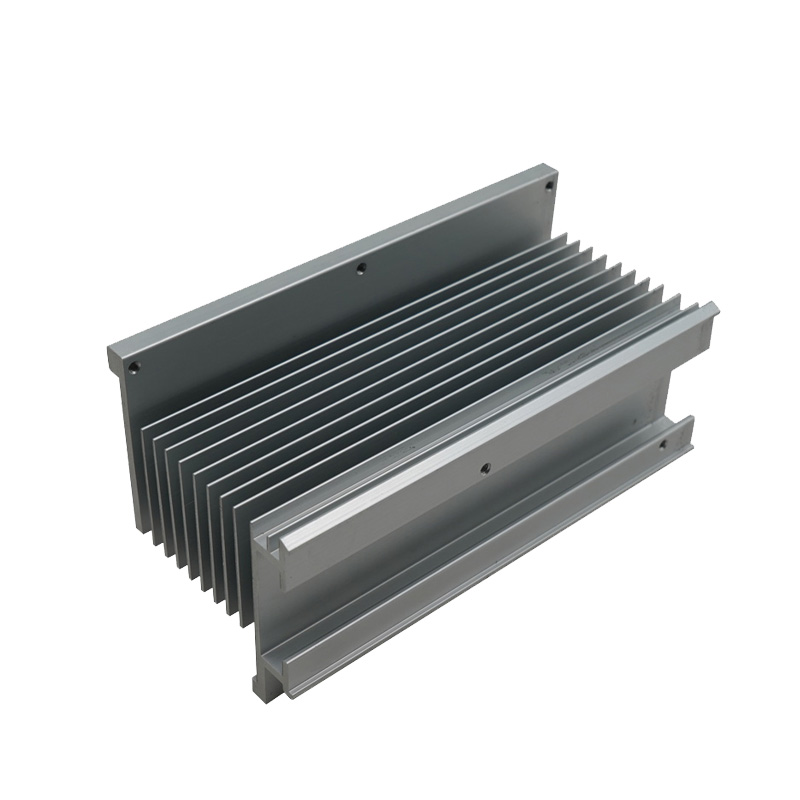

(1) Finned heat sink: Fins with increased surface area improve the heat dissipation efficiency of air convection under natural heat dissipation conditions.

Common aluminum thermal heat sink shapes: strip, radial and pin-shaped fins.

(2) Flat heat sink: Simple structure, high production volume, low cost, suitable for low-power LEDs or LED heatsinks that require fan cooling.

(3) Heat pipe + heat sink combination: Heat pipe can quickly conduct heat, and heat sink can dissipate heat, which is suitable for high-power LEDs such as street lights and car lights.

LED heatsinks application scenarios

LED light heat sink are widely used in commercial display, billboards, interior decoration lighting and other fields.

Interior decoration lighting: LED aluminum profiles can be used for decorative lighting such as walls, floors and ceilings.

LED heatsinks maintenance and management

1. For the long-term use of LED lighting, heatsinks maintenance is equally important.

2. Regularly cleaning the dust on the LED light heat sink and maintaining good ventilation can effectively extend the service life of the LED lighting heatsinks.

3. Real-time monitoring of temperature changes of lamps and timely discovery of potential risk factors can effectively avoid damage to Aluminum thermal Heat sink caused by poor heat dissipation.