Bonded Or Skived Stamped Auto Heat Sinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

Bonded or skived Heat Sinks more efficient cooling and better performance.

Skived fin Heat Sinks thin fins and high fin density capabilities.

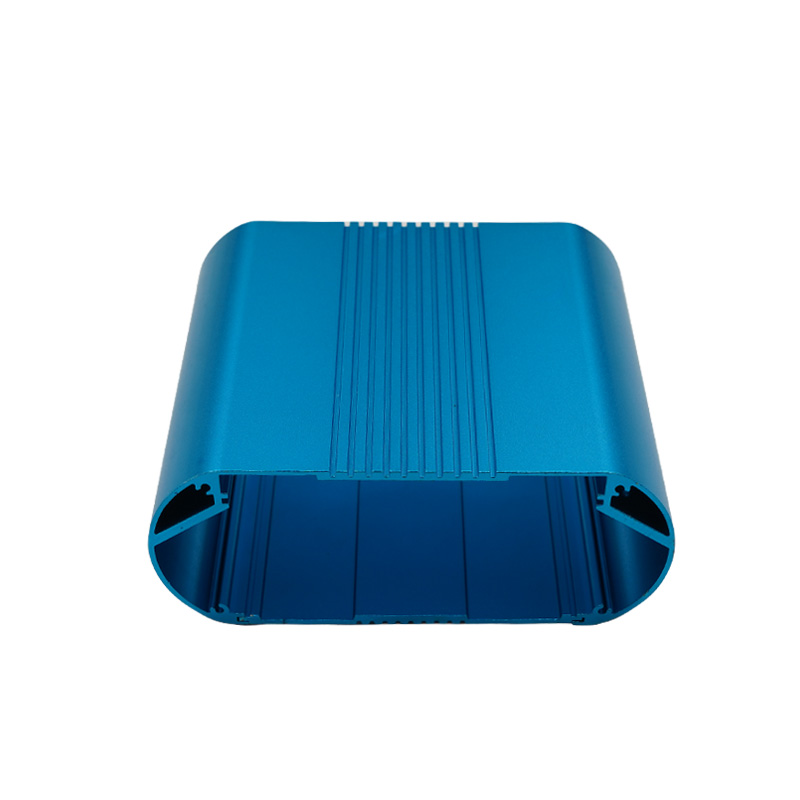

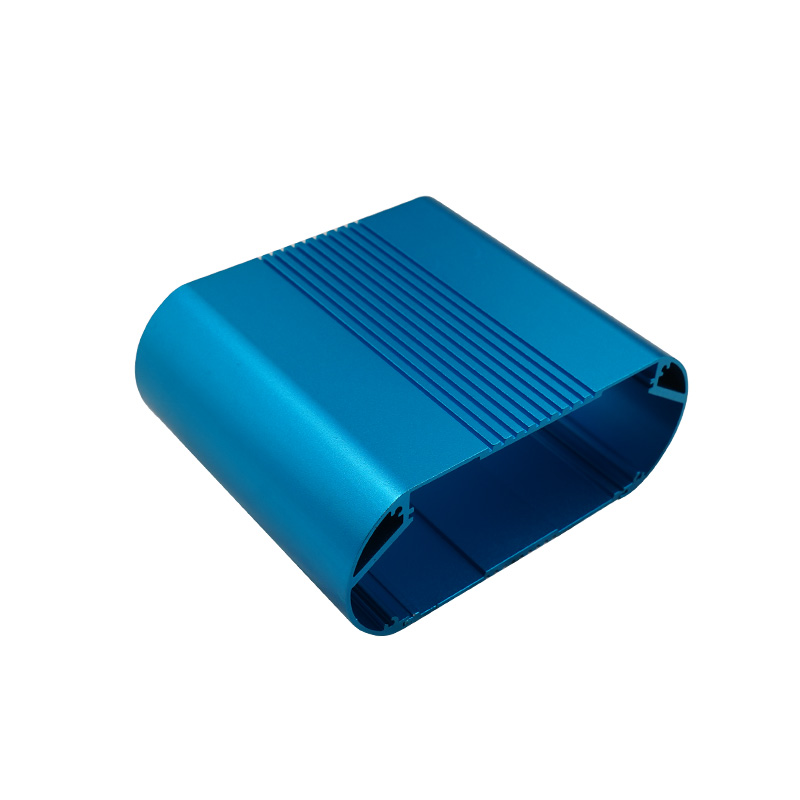

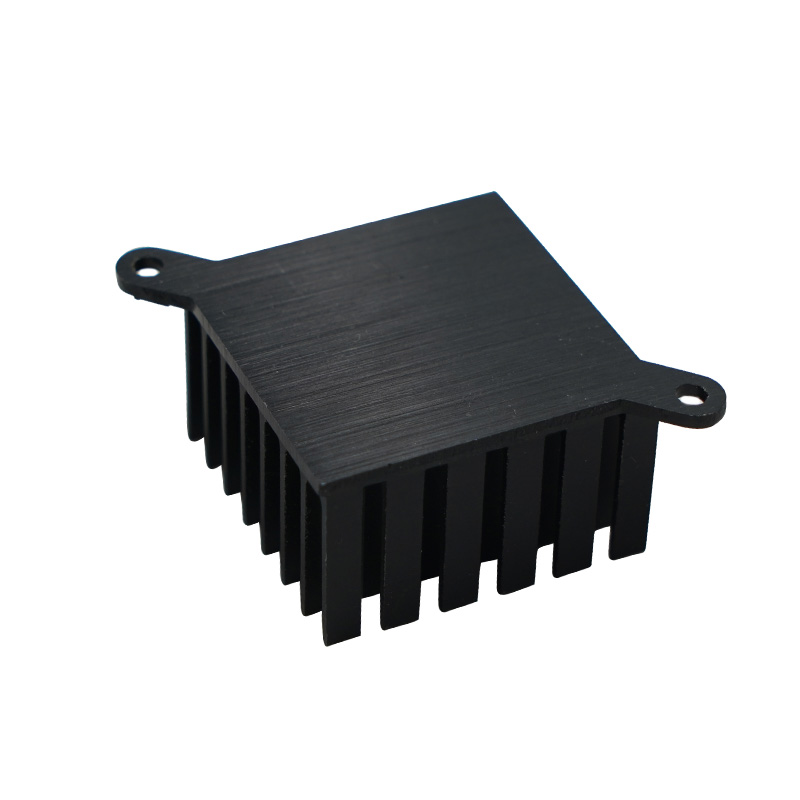

Bonded or skived Heat Sinks

Bonded fin Heat Sinks

The aspect ratio between fin gaps and fin height exceeds that of other Heat Sinks. Materials that can be used include aluminum and copper to reduce weight and improve thermal performance.Having more vertical height creates more heat transfer surface area, making Bonded or skived Heat Sinks the design more flexible and economical.

Bonded fin Heat Sinks Notes: Ensure that the thermal conductivity of the adhesive meets the heat dissipation requirements of the heat sink.Avoid applying too thick a layer to reduce thermal resistance.Long-term stability is required under high temperature conditions.

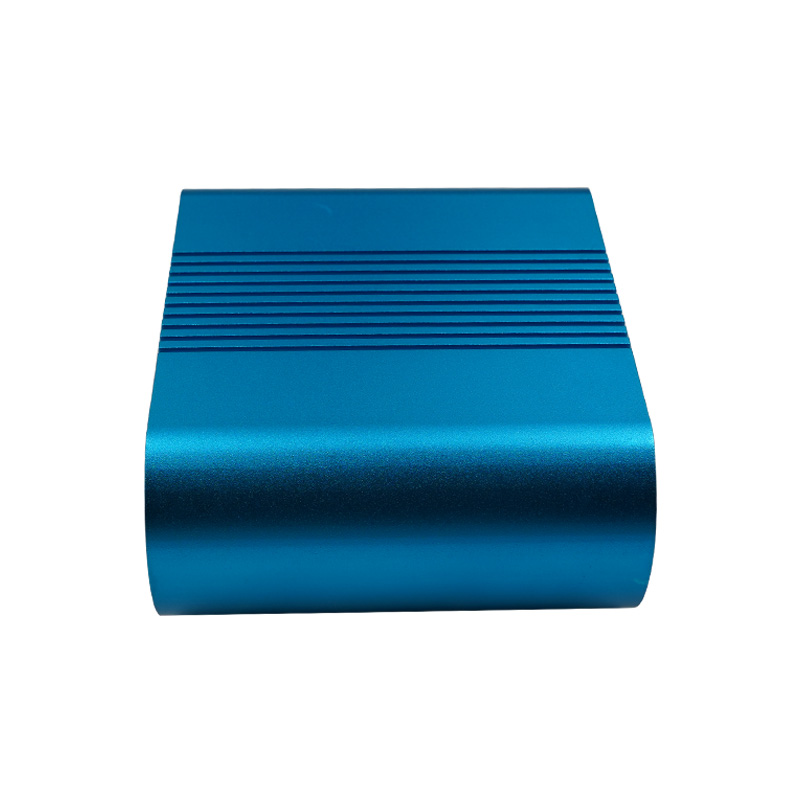

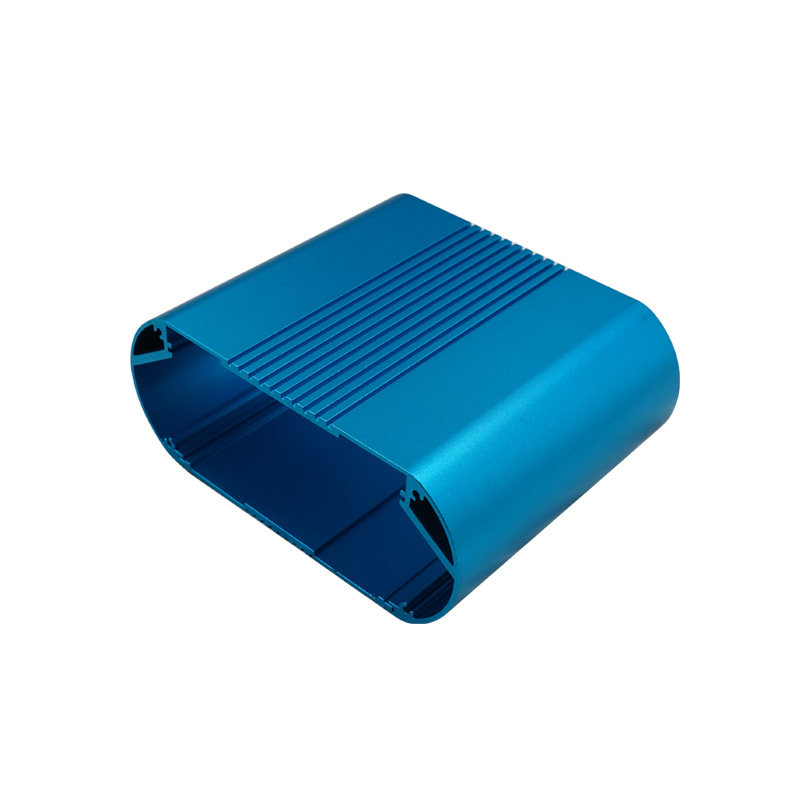

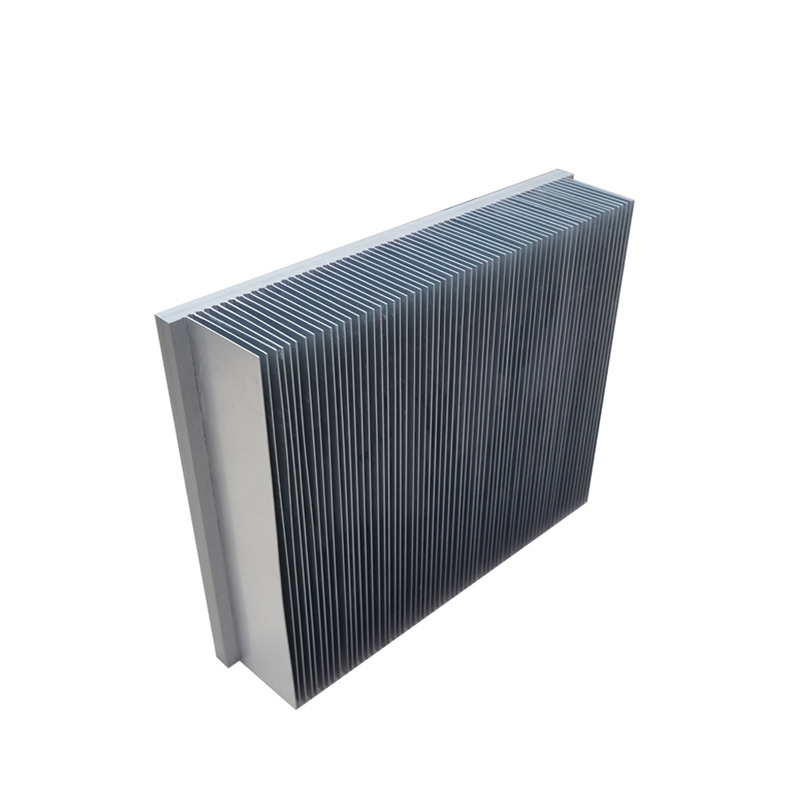

Skived Heat Sinks

Processing method made from a single piece of metal, where the layers are partially sliced from the top of the base and the folded layers are perpendicular to the base, the one-piece construction reduces thermal resistance, allowing for greater heat sink surface area and higher heat transfer, reducing costs , improve design flexibility and speed up prototyping.

When choosing to Bonded or skived Heat Sinks, you need to select a suitable heat sink based on the material properties, application scenarios and process requirements.

We can provide you with both.

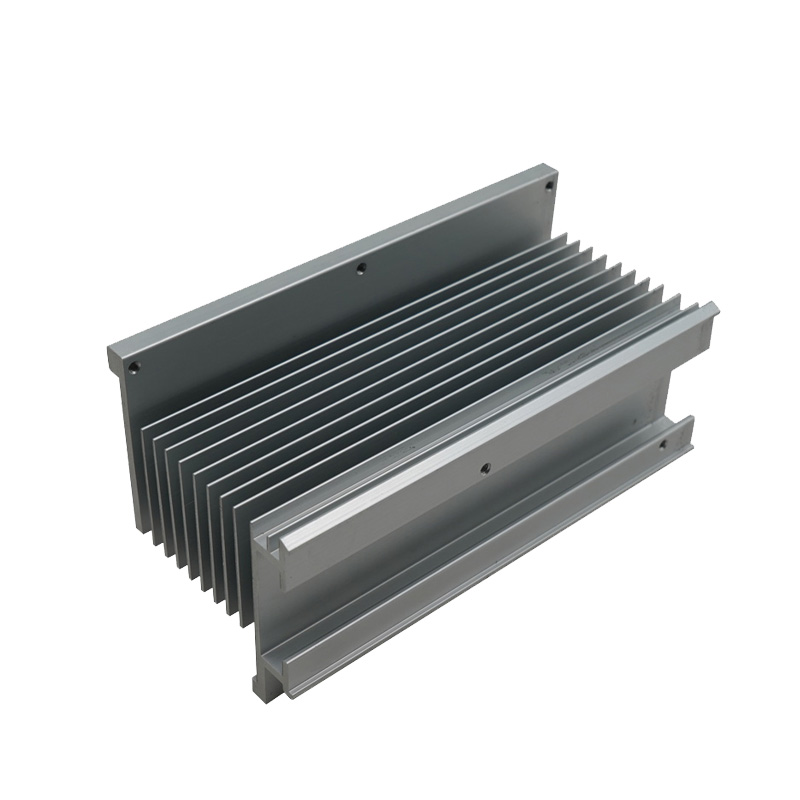

Stamped Heat Sinks

Stamped heat sinks are heat sinks made by stamping metal. Each metal part has added details and functions. The processed structure is a heat sink fin, which has high heat exchange efficiency. The geometry of stamped heat sinks is designed for specific electronic packaging types and can be applied to electronic equipment, auto heat sink parts and LED lighting, etc., with the best fit and function. Stamped heat sinks can be active or passive, based on adding fans to increase airflow. Automatic heat sink and coolant heat dissipation ensure that the engine will not fail due to high temperature.

Auto heat sink

Stamped heat sinks for the auto heat sink is a core component of the automotive cooling system manufactured by stamping technology, mainly used for heat dissipation of automotive engines, transmission oil cooling or thermal management of new energy batteries.It uses stamping technology to process materials such as aluminum, copper or stainless steel into a heat dissipation fin structure or a water chamber structure, and combines brazing or mechanical assembly to forming the heat exchange effect of an efficient auto heat sink.

Stamped auto heat sink have become one of the standard solutions for thermal management of contemporary vehicles due to their lightweight, high efficiency and low cost. As new energy vehicles increase the precision requirements for auto heat sink, continuous innovation in technology and materials will promote the development of the auto heat sink industry.