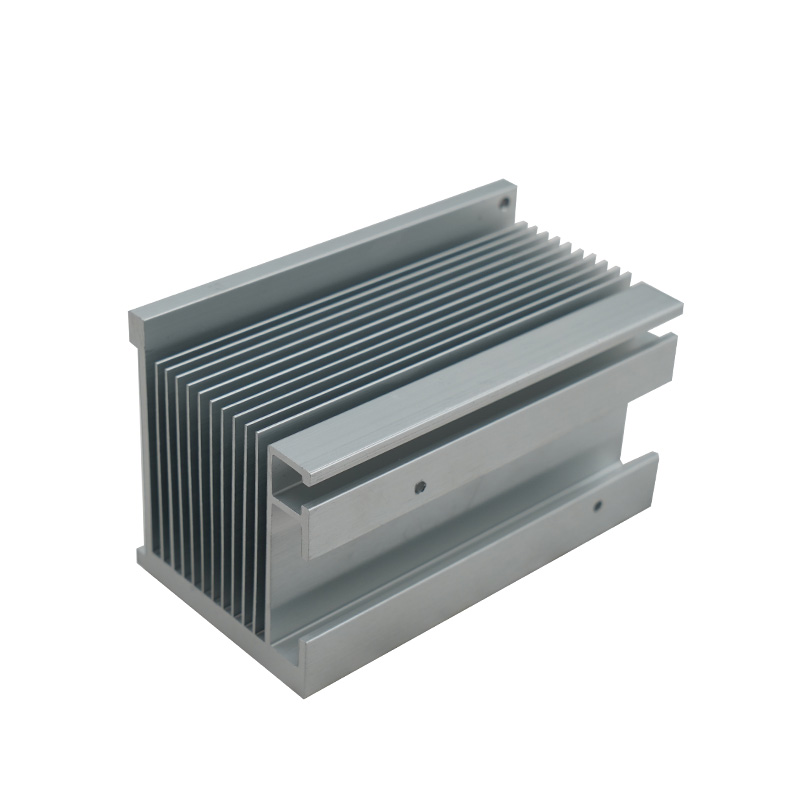

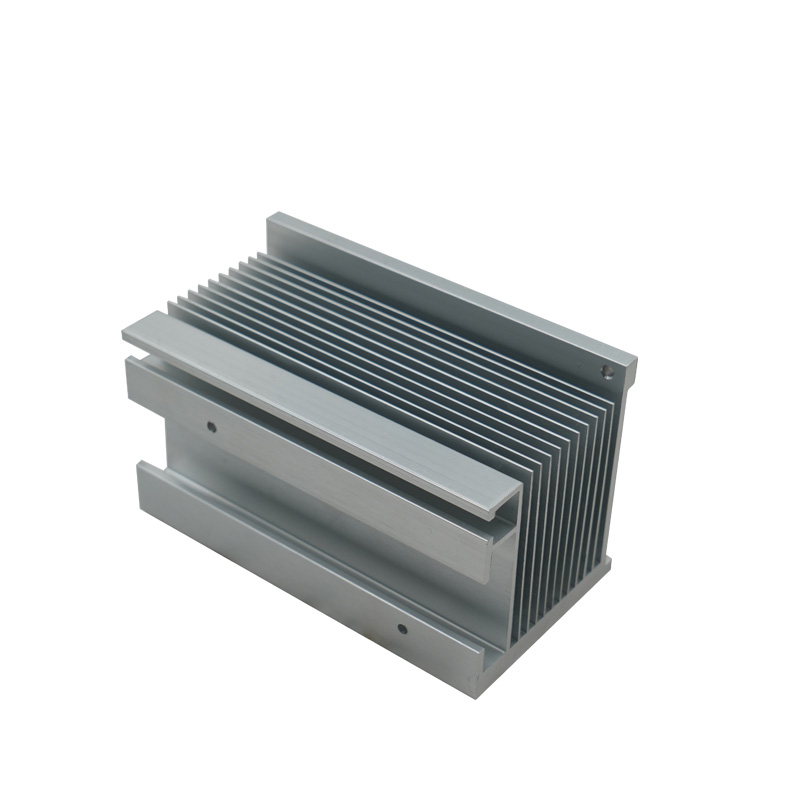

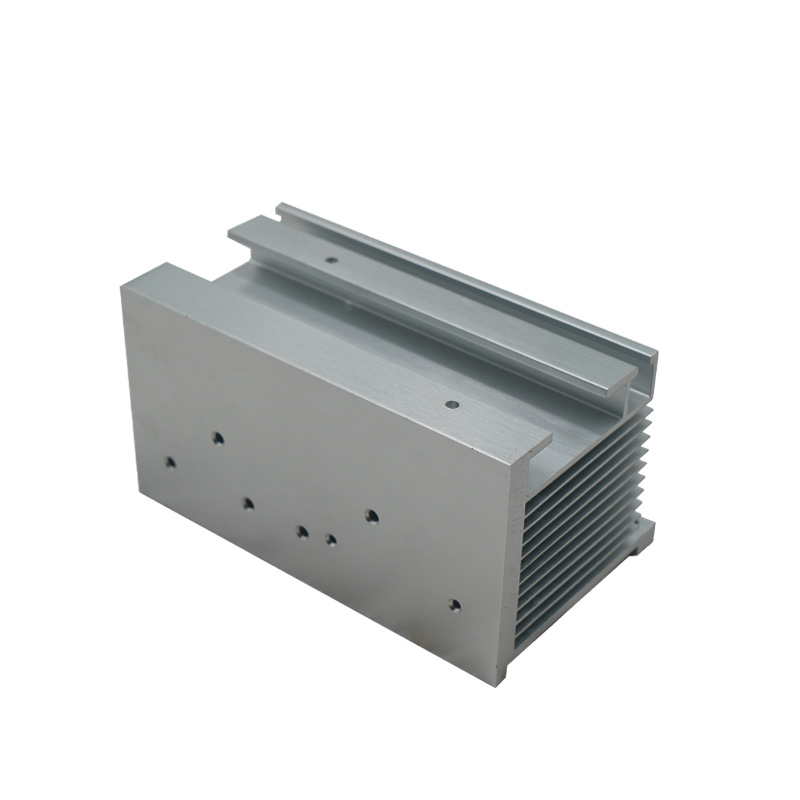

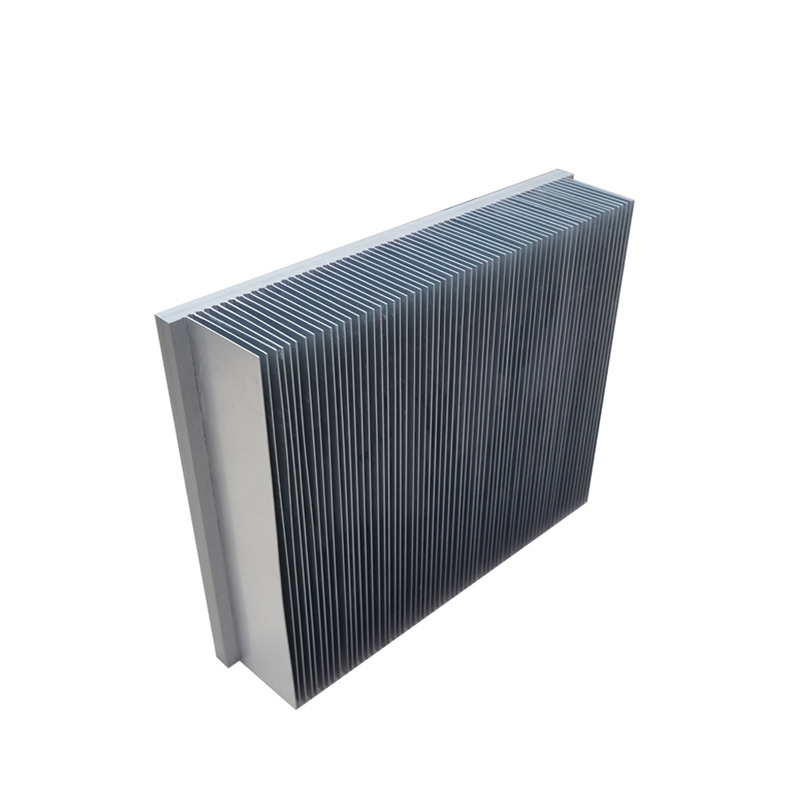

CNC Machined Aluminum Extrusion Heatsinks

Brand Customizable

Product origin Shandong, China

Delivery time 15-45days

Supply capacity Annual output 6,000 tons

CNC machined heat sinks available in custom sizes.

Target material diversity such as aluminum and aluminum alloys.

Aluminum heatsinkss Orders can be completed quickly within 15 days.

CNC Machined Heat sinks

CNC Machined Heat sinks

CNC (Computer Numerical Control) machining is the use of computer-controlled machines to remove excess material from a workpiece and shape it into the desired design shape. In aluminum heat sink manufacturing, CNC machines use milling, turning and other steps to produce precise and complex heat sink geometries. CNC machined heat sinks made by CNC machines can be customized according to thermal management requirements.

| CNC machined heat sinks | |

| Material | Aluminum 6000 series: 6061, 6063 |

| Temper | T3 - T8 |

| Length | Customized request available |

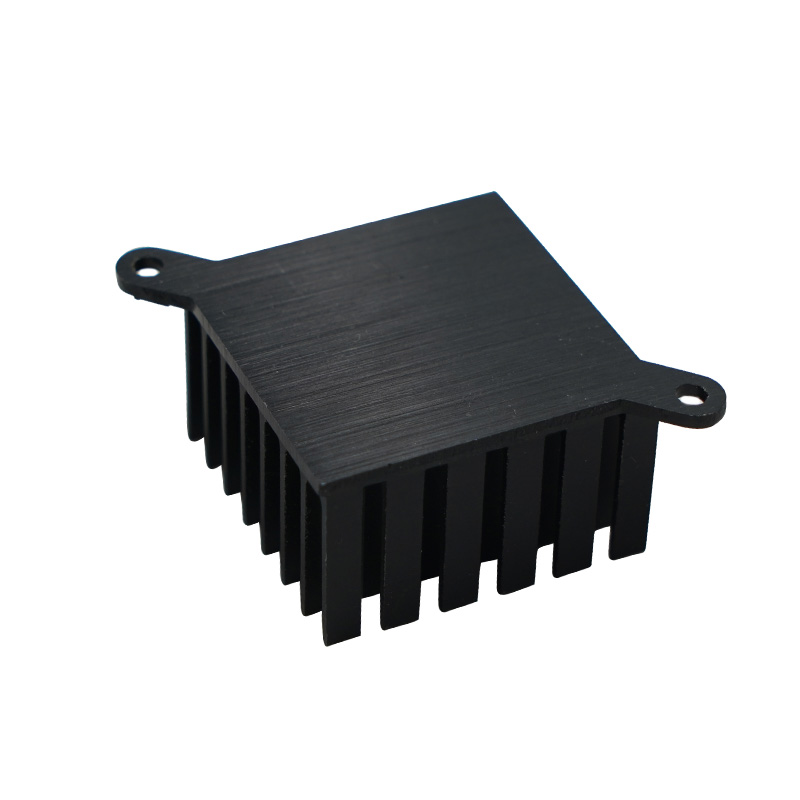

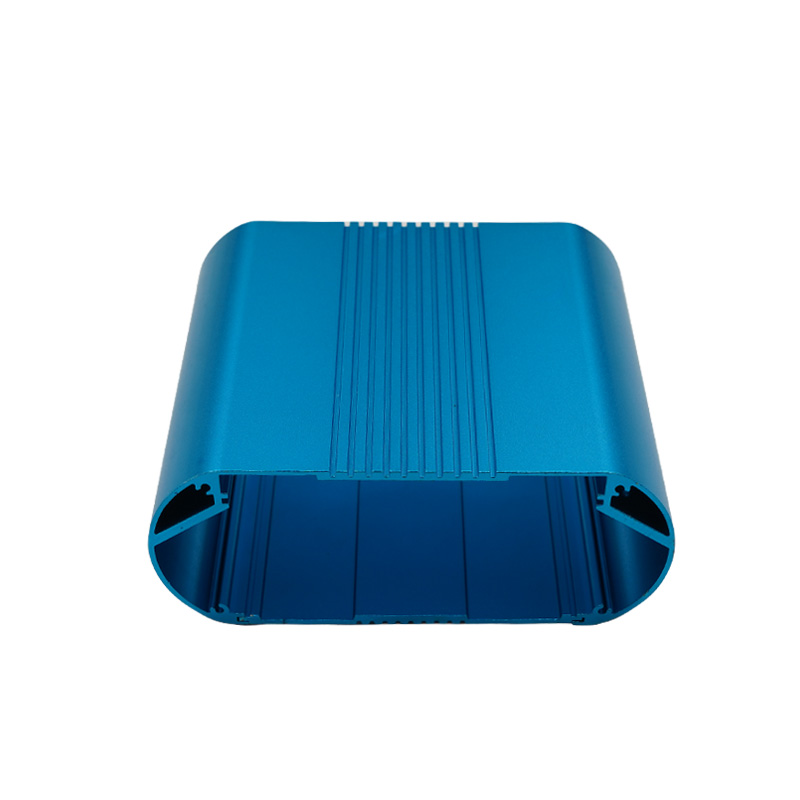

| Color | Customized color,Metal silver, champagne, black, white, mirror |

| Surface Treatment | Anodized, Powder coated, mill finish, polish, brushed |

| Certificate and Standard | ISO9001, ISO14001, IATF 16949, SGS |

| Lead Time | Die Developing and Sample testing: 15-20 days. Production: 20-30 days. |

| Payment Term | T/T 30% |

| FOB Port | Qingdao, Shandong province,China |

| Packing Details | Protection film and wooden packing, or depend on clients special requirement. |

Aluminum extrusion heatsinks or CNC machined heat sinks

Advantages:

Efficient production can reduce waste, save costs, and run large-scale production.

Aluminum heatsinks Design flexibility, aluminum heatsinks can be of any shape or size.

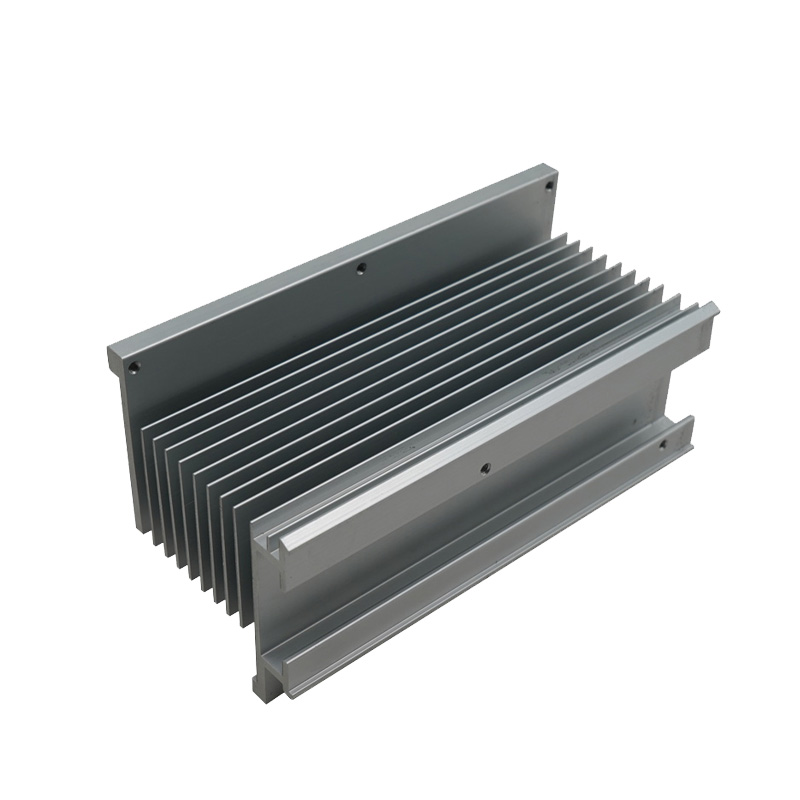

High precision and accuracy with tight tolerances, optimal thermal performance.

Extrusion heatsinks with consistent quality and uniform material properties.

Extrusion heatsinks

Extrusion Heatsinks is a heat sink manufactured by metal extrusion. Its main core principle is to transfer heat to the external environment by increasing the heat dissipation surface area of the aluminum heatsinks and optimizing its heat conduction path. Extrusion heatsinks: various heated aluminum ingots are extruded through the die under high pressure to form a heat sink matrix with dense fins. The spacing, thickness and height of the aluminum heatsinks fins can be adjusted according to different customer needs.

Extrusion Heatsinks Application scenarios: electronic equipment CPU heat sinks, LED lighting fixtures, industrial equipment and automotive electronics, etc.

Common problems: The fins are easy to deform. You can increase the root thickness of the aluminum heat sink, or use a support structure to reinforce the fins of the heat sink. Contact thermal resistance, use relevant materials (such as thermal grease) to improve heat transfer on the contact surface.

Optimization direction: Target the hot spots of aluminum heatsinks and combine heat pipes. Anodize or spray high-emissivity coatings (such as black/blue aluminum oxide for surface treatment. Fluid simulation, optimize airflow paths through CFD simulation.